- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

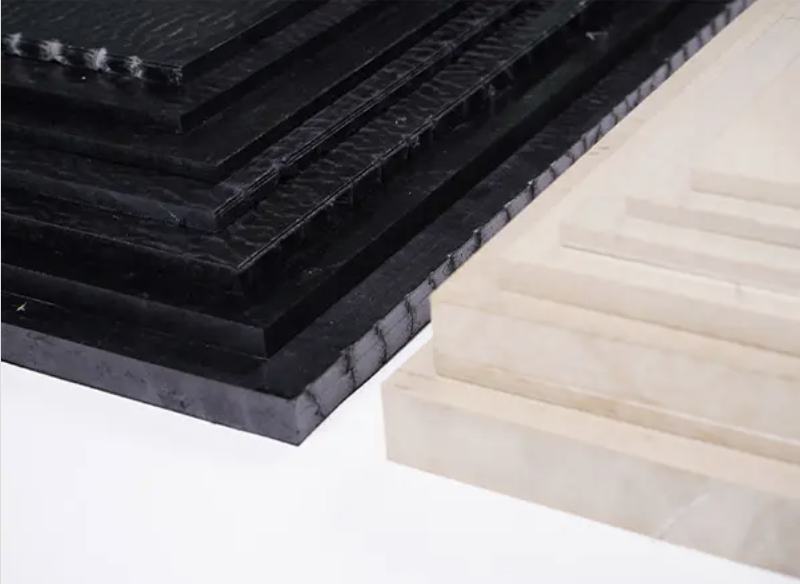

What makes PSU Sheet a standout in the world of engineering plastics? As industries evolve, the demand for materials that offer exceptional thermal stability, chemical resistance, and mechanical strength grows. PSU Sheet meets these needs, offering a reliable solution for challenging applications. In this post, you'll learn about PSU Sheet's unique properties, its role in engineering, and why it's crucial for demanding environments.

Polyphenylsulfone (PSU) is a high-performance engineering plastic known for its exceptional properties, making it a go-to material in demanding applications. Understanding its chemical makeup and characteristics helps explain why PSU stands out among other engineering plastics.

PSU is a thermoplastic polymer composed mainly of repeating units of phenyl groups linked by sulfone (–SO2–) groups. This unique structure combines aromatic rings with sulfone linkages, granting the material outstanding thermal and chemical stability. The aromatic rings provide rigidity and strength, while the sulfone groups contribute to excellent resistance against oxidation and chemical attack. This combination results in a polymer that maintains its integrity under harsh conditions.

● Thermal Resistance: PSU exhibits a high glass transition temperature (Tg) around 190°C, allowing it to withstand elevated temperatures without deforming. This thermal stability ensures its performance in applications involving heat exposure.

● Chemical Resistance: The sulfone groups in PSU make it resistant to acids, bases, and hydrocarbons. This resistance extends the lifespan of PSU components in corrosive environments.

● Mechanical Strength: PSU shows impressive tensile and flexural strength, enabling it to bear heavy loads and mechanical stress without cracking or breaking.

● Electrical Insulation: It has excellent dielectric strength, making PSU ideal for electrical and electronic components requiring reliable insulation.

● Dimensional Stability: PSU maintains its shape and size even when subjected to temperature fluctuations, which is critical for precision engineering parts.

Compared to other engineering plastics like Polyetheretherketone (PEEK), Polyetherimide (PEI), and Polyphenylene Oxide (PPO), PSU offers a balanced combination of properties:

Property | PSU | PEEK | PEI | PPO |

Glass Transition Temp | ~190°C | ~143°C | ~217°C | ~215°C |

Chemical Resistance | High | Very High | High | Moderate |

Mechanical Strength | High | Very High | High | Moderate |

Cost | Moderate | High | High | Moderate |

Processability | Good | Moderate | Moderate | Good |

PSU often provides a cost-effective alternative to PEEK and PEI, especially where extreme temperature resistance is needed without the highest cost.

PSU’s unique chemical composition gives it a rare mix of heat resistance, chemical durability, mechanical strength, and electrical insulation. These properties make PSU sheets ideal for challenging engineering applications where materials must perform reliably in tough environments.

Tip: When selecting engineering plastics, consider PSU sheet for applications requiring high thermal stability and chemical resistance at a moderate cost compared to high-end polymers like PEEK.

Polyphenylsulfone (PSU) sheet is well-known for its exceptional thermal stability, a key reason it’s favored in engineering plastics. This thermal stability comes from two important temperature ratings: the high glass transition temperature and the continuous use temperature.

PSU has a glass transition temperature around 190°C. This means it can handle heat up to this point without its structure becoming soft or losing strength. The high Tg is crucial because it ensures that PSU parts won’t warp or deform under heat that would damage many other plastics. For example, in aerospace applications, components face rapid temperature changes and high heat; PSU’s high Tg keeps parts reliable and safe.

Beyond the glass transition temperature, PSU also boasts a high continuous use temperature, often close to 160°C or more. This rating tells us how hot the material can get during long-term use without performance loss. PSU’s high CUT makes it perfect for environments where heat exposure lasts for hours or days, like oil and gas equipment or industrial machinery. It won’t break down or weaken even after extended heat exposure.

PSU’s thermal stability opens doors to many demanding applications:

● Aerospace Components: Parts endure extreme heat during flight and re-entry. PSU maintains strength and shape, ensuring safety.

● Oil and Gas Equipment: Drilling tools and seals face hot, harsh conditions. PSU resists heat, extending equipment life.

● Automotive Parts: Engine components get hot during operation. PSU handles this heat while providing durability.

● Electrical Housings: Devices that generate heat need materials that won’t melt or deform. PSU’s thermal resistance protects internal parts.

Because of its thermal properties, PSU often replaces metals or ceramics in some parts, offering lighter weight and easier manufacturing while still withstanding heat.

Tip: When designing parts for continuous high-heat exposure, choose PSU sheet for its ability to maintain strength and shape, reducing the risk of failure in extreme temperature environments.

Polyphenylsulfone (PSU) sheet is highly prized in engineering for its outstanding chemical resistance. This feature allows PSU to perform reliably in environments where exposure to harsh chemicals is common, making it a top choice for many industrial applications.

PSU’s molecular structure includes sulfone groups that provide excellent resistance to a wide range of chemicals. It can withstand exposure to strong acids, bases, and hydrocarbons without degrading or losing mechanical strength. This resistance means PSU components maintain their integrity even when in contact with corrosive substances, unlike many other plastics that might swell, crack, or dissolve.

For example, in chemical processing plants, PSU sheets are used to fabricate parts that come into direct contact with acidic or alkaline solutions. Its ability to resist hydrocarbons also makes it suitable for oil and gas applications, where exposure to fuels and lubricants is routine.

Thanks to its chemical resilience, PSU offers extended service life in aggressive environments. Unlike materials that wear down quickly, PSU sheets can endure continuous chemical exposure without significant deterioration. This longevity reduces maintenance costs and downtime in critical applications.

In laboratory settings, where cleaning agents and solvents are frequently used, PSU sheets hold up well, ensuring that precision instruments and protective barriers remain functional over time.

Industries that benefit from PSU’s chemical resistance include:

● Chemical Processing: Tanks, pipes, and valves made from PSU resist corrosion from reactive chemicals.

● Oil and Gas: Seals, gaskets, and components exposed to hydrocarbons and drilling fluids perform reliably.

● Medical Devices: PSU’s chemical stability supports sterilization processes involving harsh agents.

● Electrical and Electronics: Components resist degradation from cleaning solvents and environmental contaminants.

This broad chemical resistance, combined with PSU’s other strengths, makes it a versatile material in engineering applications where durability and reliability are non-negotiable.

Tip: When selecting materials for applications exposed to corrosive chemicals, consider PSU sheet for its proven ability to resist acids, bases, and hydrocarbons, ensuring long-lasting performance and reduced maintenance.

Polyphenylsulfone (PSU) sheet is highly valued in engineering for its impressive mechanical strength and durability. These qualities make it a top choice for applications where materials must endure heavy loads and tough conditions without failure.

PSU exhibits remarkable tensile strength, meaning it can resist forces that try to pull it apart. This ability is vital in structural components that face stretching or tension, such as parts in vehicles or aerospace frames. Alongside tensile strength, PSU also offers excellent flexural strength. This means it can withstand bending or twisting forces without cracking or breaking. Such flexural resilience ensures PSU parts maintain their shape and function even under mechanical stress.

These strengths come from the material’s chemical structure, which combines rigid aromatic rings and strong sulfone linkages. Together, they provide both stiffness and toughness, allowing PSU to absorb and distribute mechanical forces effectively.

Thanks to its mechanical robustness, PSU sheet is used in many high-load engineering environments:

● Aerospace: Structural parts that must endure vibration, pressure, and impact.

● Automotive: Engine components, brackets, and housings that face constant mechanical stress.

● Industrial Machinery: Gears, rollers, and other parts that carry heavy loads.

● Medical Devices: Durable components in surgical tools and equipment.

In these settings, PSU’s ability to maintain strength over time reduces the risk of component failure, enhancing safety and reliability.

When compared to other high-strength engineering plastics like PEEK and PEI, PSU offers a balanced mix of strength and cost-effectiveness. While PEEK may provide higher mechanical strength, PSU is often preferred for applications where excellent durability is needed at a lower price point. Additionally, PSU processes more easily than some high-performance plastics, which can reduce manufacturing complexity.

Material | Tensile Strength | Flexural Strength | Cost | Processability |

PSU | High | High | Moderate | Good |

PEEK | Very High | Very High | High | Moderate |

PEI | High | High | High | Moderate |

This balance makes PSU sheet a practical choice for engineers who need strong, durable materials without excessive costs.

Tip: Choose PSU sheet for parts requiring excellent tensile and flexural strength, especially when balancing performance and manufacturing costs in high-load applications.

Polyphenylsulfone (PSU) sheet is highly regarded for its excellent electrical insulation capabilities. This makes it a preferred material in electrical and electronics engineering, where safety and reliability are critical.

PSU exhibits a high dielectric strength, meaning it can withstand strong electric fields without breaking down. This property prevents current leakage and electrical shorts, which are crucial for maintaining the integrity of electrical devices. Its insulation resistance is also impressive, allowing PSU to act as a barrier against unwanted electrical flow.

These electrical properties stem from PSU’s molecular structure, which resists the movement of electric charges. This makes PSU sheets ideal for insulating components that operate under high voltage or in sensitive electronic circuits.

PSU sheets are widely used in various electrical and electronic components, including:

● Insulating parts in circuit boards: PSU prevents electrical shorts and protects delicate components.

● Connectors and sockets: It ensures safe and reliable connections by isolating electrical contacts.

● Switchgear and control panels: PSU withstands electrical stress and heat, maintaining performance over time.

● Electrical housings: It protects internal electronics from environmental factors while providing insulation.

Its ability to combine electrical insulation with thermal stability and mechanical strength makes PSU a versatile choice in these fields.

Using PSU sheets in electrical applications reduces the risk of failures caused by electrical breakdown or insulation degradation. It helps prevent:

● Short circuits due to insulation failure.

● Electrical arcing that can damage components.

● Heat buildup from poor insulation leading to overheating.

By maintaining stable insulation even under harsh conditions, PSU ensures longer service life and safer operation of electrical devices.

Tip: Select PSU sheet for electrical parts requiring high dielectric strength and insulation resistance to enhance device safety and reliability in demanding environments.

Dimensional stability means a material keeps its shape and size even when temperatures change or it faces stress. PSU sheet is excellent at this, making it a favorite in precision engineering where exact dimensions matter.

Materials expand when heated and contract when cooled. Too much change can cause parts to warp or fail. PSU sheet resists these changes well due to its strong molecular structure. The aromatic rings and sulfone groups in PSU create a rigid framework that doesn’t easily stretch or shrink. This means PSU parts stay true to their size across a wide temperature range, reducing the risk of mechanical failure or misalignment.

For example, in aerospace or medical devices, even tiny dimensional changes can cause big problems. PSU’s low thermal expansion ensures components fit perfectly, maintaining performance and safety.

Precision engineering relies on materials that don’t change shape under stress or heat. PSU’s dimensional stability supports tight tolerances needed in:

● Aerospace parts that face extreme temperature swings.

● Medical instruments needing exact measurements.

● Electrical connectors where spacing affects function.

● Industrial machinery requiring parts to align perfectly.

Using PSU sheet means engineers can trust their designs will hold up, reducing rework and downtime.

Compared to other plastics like PEEK, PEI, and PPSU, PSU offers a strong balance:

Property | PSU | PEEK | PEI | PPSU |

Coefficient of Thermal Expansion (CTE) | Moderate (around 50 µm/m·°C) | Low (about 47 µm/m·°C) | Moderate (around 54 µm/m·°C) | Low (about 50 µm/m·°C) |

Dimensional Stability | High | Very High | High | Very High |

Cost | Moderate | High | High | High |

Processability | Good | Moderate | Moderate | Moderate |

While PEEK and PPSU have slightly better dimensional stability, PSU offers a cost-effective alternative that still meets most precision needs. Its easier processing also helps reduce manufacturing costs.

Tip: For applications demanding tight dimensional tolerances under temperature changes, choose PSU sheet to ensure parts maintain shape and fit, minimizing costly errors in precision engineering.

Polyphenylsulfone (PSU) sheet is widely used across industries thanks to its unique blend of properties like heat resistance, chemical stability, and mechanical strength. Let’s explore some of the key real-world applications where PSU truly shines.

In aerospace, materials must handle extreme temperature swings, mechanical stress, and exposure to chemicals. PSU sheet fits perfectly here. It is used in structural parts, interior components, and insulation panels. Its high glass transition temperature keeps parts from deforming during flight. Plus, its chemical resistance protects against hydraulic fluids and fuels. Using PSU helps reduce weight compared to metals, improving fuel efficiency without sacrificing safety.

PSU’s biocompatibility and sterilization tolerance make it ideal for medical devices. It’s used in surgical instruments, diagnostic equipment, and housings for medical electronics. PSU withstands repeated sterilization cycles using steam or chemicals without losing strength or shape. This durability ensures patient safety and device reliability. Its electrical insulation also protects sensitive electronics inside medical tools.

Oil and gas operations often face harsh chemical exposure and high temperatures. PSU sheet resists acids, bases, and hydrocarbons found in drilling fluids and fuels. This resistance extends equipment life, reducing downtime and maintenance costs. PSU is used in seals, gaskets, valve components, and protective housings. Its mechanical strength ensures parts hold up under pressure and mechanical stress in drilling or extraction environments.

PSU’s electrical insulation properties and thermal stability make it a top choice for electrical connectors, switchgear, and circuit board components. It prevents electrical failures caused by insulation breakdown or heat damage. PSU parts protect delicate electronics from environmental contaminants and mechanical wear. Its dimensional stability ensures precise fits in connectors and housings, maintaining reliable electrical performance.

Tip: For industries needing materials that combine heat resistance, chemical durability, and mechanical strength, PSU sheet offers a versatile solution proven in aerospace, medical, oil and gas, and electrical applications.

Polyphenylsulfone (PSU) sheet stands out in engineering plastics due to its exceptional thermal stability, chemical resistance, mechanical strength, and electrical insulation. As industries demand materials that endure extreme conditions, PSU's role is poised to expand, offering reliable solutions across aerospace, medical, oil and gas, and electronics sectors. When selecting materials for challenging environments, consider PSU for its unique benefits. Suzhou Jutai HPM Co., Ltd. provides high-quality PSU sheets that deliver unmatched value and performance.

A: A PSU Sheet, made from polyphenylsulfone, is a high-performance engineering plastic known for its thermal stability, chemical resistance, and mechanical strength.

A: PSU Sheet is preferred in aerospace for its high glass transition temperature and mechanical strength, ensuring parts remain stable under extreme temperatures and stress.

A: PSU Sheet is more cost-effective than PEEK, offering a balance of thermal resistance and mechanical strength at a moderate price.

A: PSU Sheet provides excellent electrical insulation and thermal stability, preventing electrical failures and maintaining device safety.

A: Yes, PSU Sheet resists acids, bases, and hydrocarbons, making it ideal for environments with chemical exposure.