- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

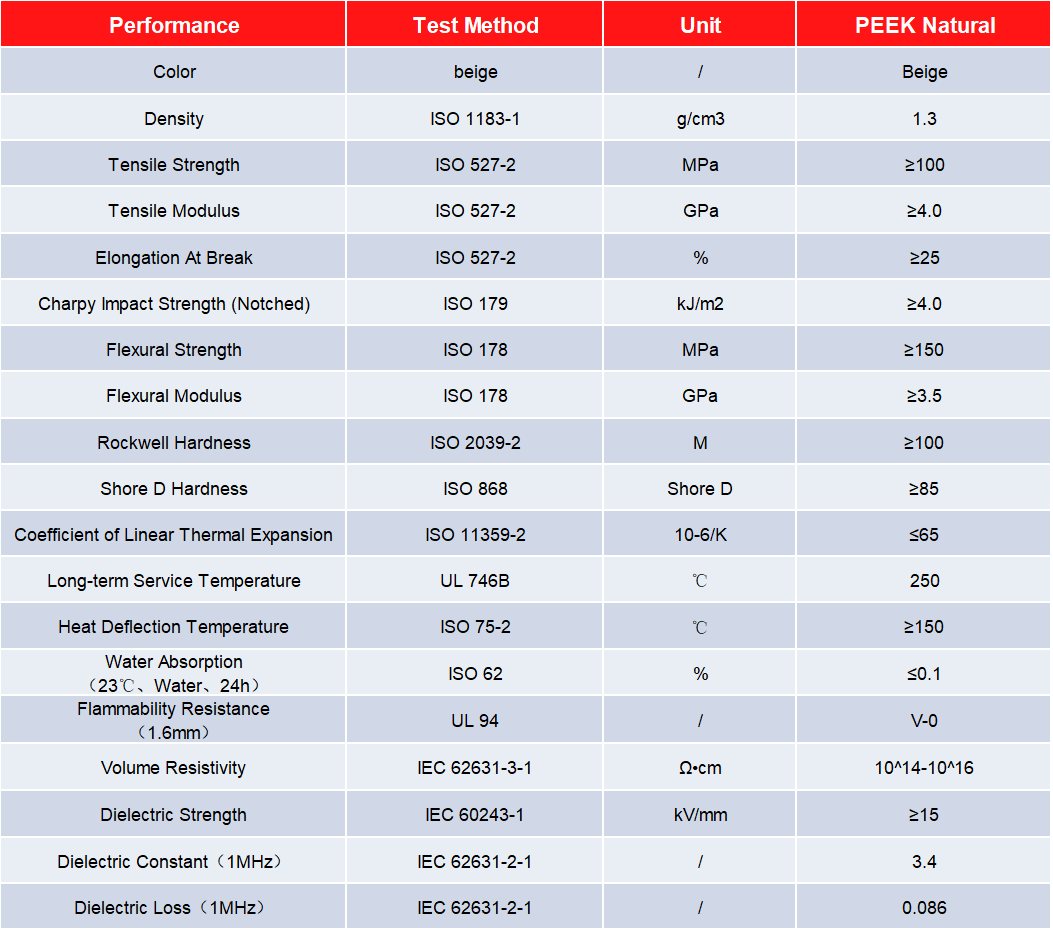

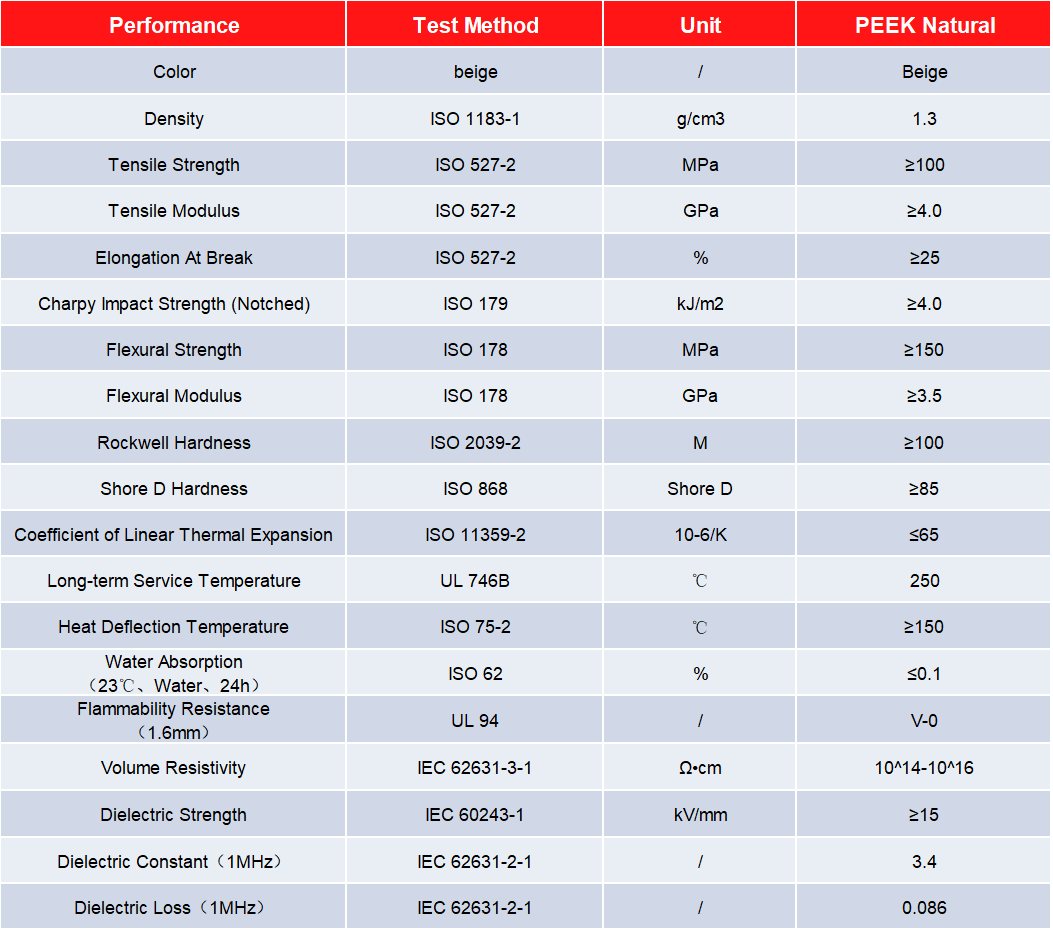

| JUTAIPEEK®NA is made from pure polyetheretherketone (PEEK) resin, typically in a beige color. long-term service temperature up to 240–260°C | |||||||||

JUTAIPEEK®NA is typically beige in color and exhibits high-temperature stability.

PEEK material can be used for extended periods at high temperatures while maintaining its mechanical properties and dimensional stability.

(long-term service temperature up to 240–260°C)

Excellent Mechanical Properties

PEEK possesses high strength, high stiffness, and good toughness, making it suitable for applications involving high loads and impact resistance.

Corrosion Resistance

PEEK demonstrates outstanding resistance to many chemicals, including acids, alkalis, and solvents.

PEEK material has excellent wear resistance, maintaining stable frictional performance under high-speed and high-pressure conditions.

PEEK is an outstanding insulating material with excellent electrical insulation properties and high-voltage resistance.

PEEK is increasingly being adopted in the energy sector due to its exceptional properties, including high heat resistance, radiation resistance, hydrolysis resistance, self-lubrication, chemical corrosion resistance, and outstanding electrical performance. include: Subsea umbilical cables and pipelines, Electrical wires and cables, Electrical connectors, Downhole sensors, Bearings, bushings, gears, and support rings

PEEK is widely used in electronic components such as computers, mobile phones, printed circuit boards, printers, LEDs, batteries, switches, connector plugs, and hard disk drives due to its outstanding properties: High-temperature resistance, Wear resistance, Corrosion resistance, Low volatility, Minimal outgassing, Low moisture absorption, Environmentally friendly flame retardancy, Dimensional stability, Processing flexibility

Aerospace Industry

PEEK is increasingly replacing aluminum and other metallic materials in aircraft component manufacturing due to its exceptional strength, chemical inertness, flame retardancy, and precision machinability for high-tolerance parts.

PEEK can withstand over 3,000 cycles of high-pressure sterilization at 134°C. The resin maintains high mechanical strength, excellent stress resistance, and hydrolytic stability when exposed to hot water, steam, solvents, and chemicals, making it ideal for manufacturing medical devices requiring repeated steam sterilization.

Automotive Industry

PEEK's superior thermomechanical properties, wear resistance, low density, and processability enable the production of automotive components such as bearings, gaskets, seals, and clutch gear rings. Its use reduces weight by up to 90% while significantly lowering manufacturing costs, with applications spanning transmission, braking, and air conditioning systems

PEEK resin is widely used to manufacture compressor valve plates, piston rings, seals, as well as various chemical pump bodies and valve components.

Semiconductor Industry

PEEK polymer materials demonstrate significant advantages throughout semiconductor manufacturing processes, including wafer production, front-end processing, fabrication, inspection, and back-end treatment.

JUTAIPEEK®NA is typically beige in color and exhibits high-temperature stability.

PEEK material can be used for extended periods at high temperatures while maintaining its mechanical properties and dimensional stability.

(long-term service temperature up to 240–260°C)

Excellent Mechanical Properties

PEEK possesses high strength, high stiffness, and good toughness, making it suitable for applications involving high loads and impact resistance.

Corrosion Resistance

PEEK demonstrates outstanding resistance to many chemicals, including acids, alkalis, and solvents.

PEEK material has excellent wear resistance, maintaining stable frictional performance under high-speed and high-pressure conditions.

PEEK is an outstanding insulating material with excellent electrical insulation properties and high-voltage resistance.

PEEK is increasingly being adopted in the energy sector due to its exceptional properties, including high heat resistance, radiation resistance, hydrolysis resistance, self-lubrication, chemical corrosion resistance, and outstanding electrical performance. include: Subsea umbilical cables and pipelines, Electrical wires and cables, Electrical connectors, Downhole sensors, Bearings, bushings, gears, and support rings

PEEK is widely used in electronic components such as computers, mobile phones, printed circuit boards, printers, LEDs, batteries, switches, connector plugs, and hard disk drives due to its outstanding properties: High-temperature resistance, Wear resistance, Corrosion resistance, Low volatility, Minimal outgassing, Low moisture absorption, Environmentally friendly flame retardancy, Dimensional stability, Processing flexibility

Aerospace Industry

PEEK is increasingly replacing aluminum and other metallic materials in aircraft component manufacturing due to its exceptional strength, chemical inertness, flame retardancy, and precision machinability for high-tolerance parts.

PEEK can withstand over 3,000 cycles of high-pressure sterilization at 134°C. The resin maintains high mechanical strength, excellent stress resistance, and hydrolytic stability when exposed to hot water, steam, solvents, and chemicals, making it ideal for manufacturing medical devices requiring repeated steam sterilization.

Automotive Industry

PEEK's superior thermomechanical properties, wear resistance, low density, and processability enable the production of automotive components such as bearings, gaskets, seals, and clutch gear rings. Its use reduces weight by up to 90% while significantly lowering manufacturing costs, with applications spanning transmission, braking, and air conditioning systems

PEEK resin is widely used to manufacture compressor valve plates, piston rings, seals, as well as various chemical pump bodies and valve components.

Semiconductor Industry

PEEK polymer materials demonstrate significant advantages throughout semiconductor manufacturing processes, including wafer production, front-end processing, fabrication, inspection, and back-end treatment.