- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

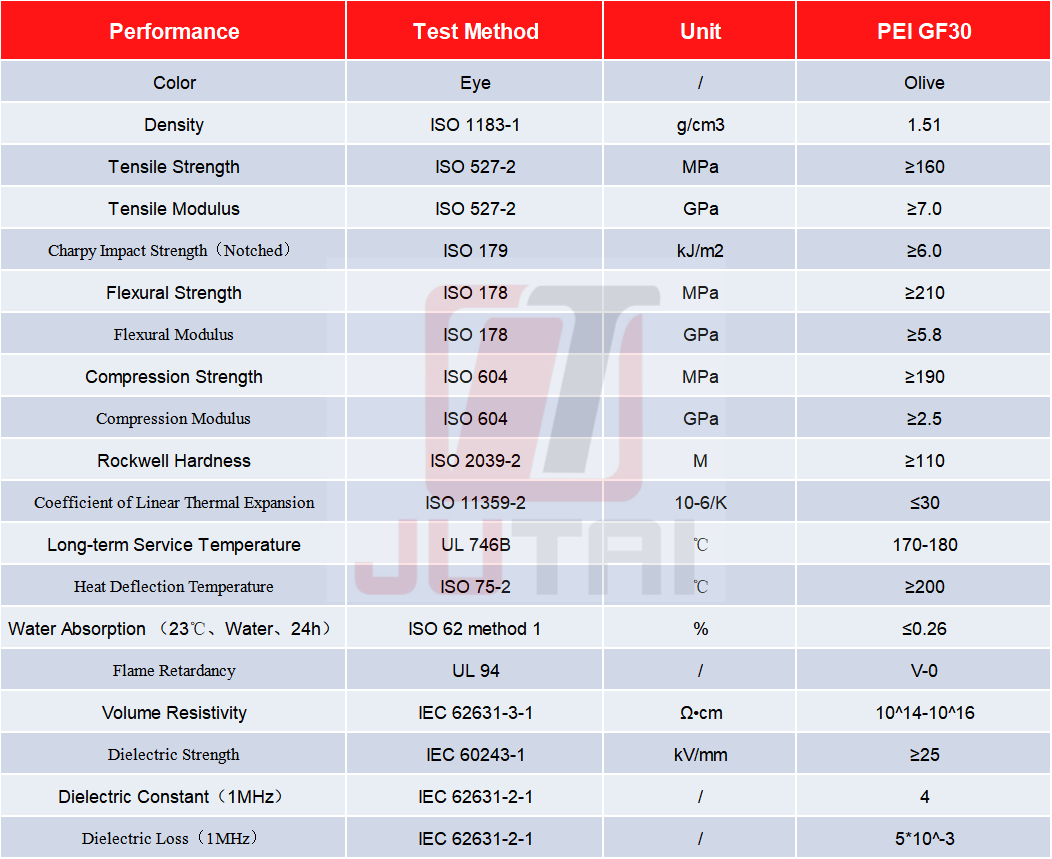

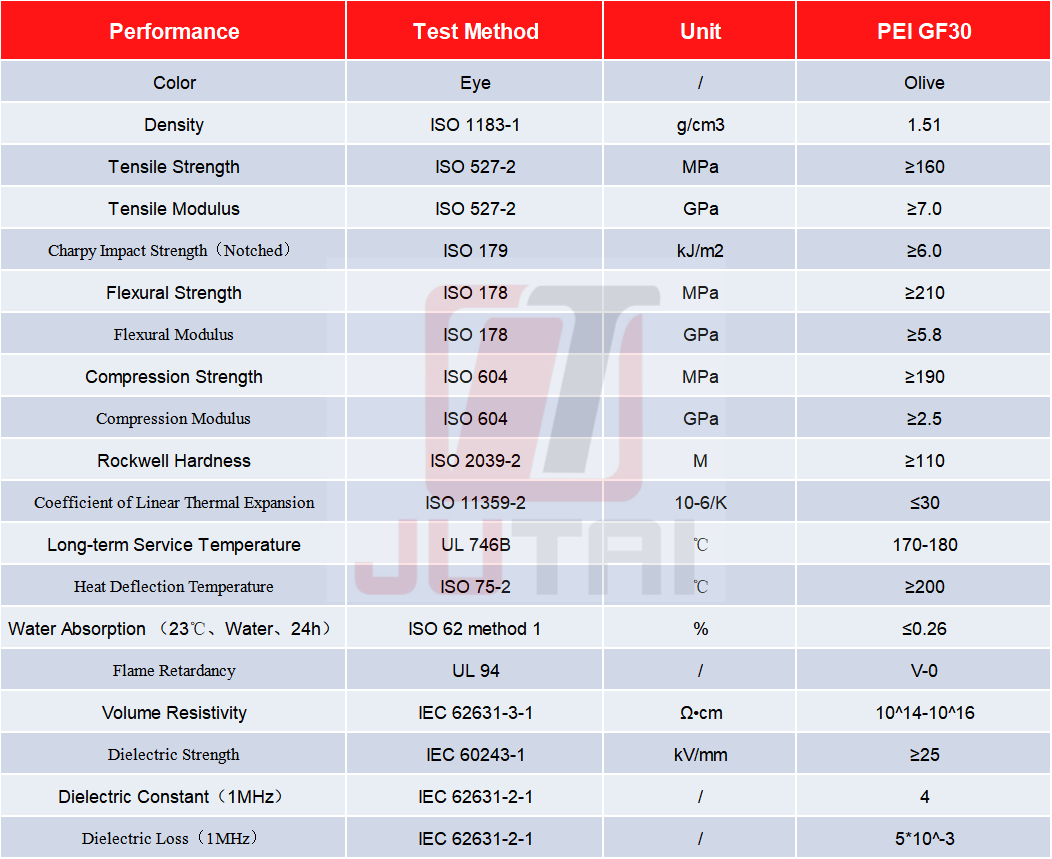

| JTYPEI®GF30 is a 30% short glass fiber reinforced polyetherimide (PEI) profile. Resin chose Sabic Ultem 2300. | |||||||||

With 30% glass fiber reinforcement, JTYPEI®GF30 exhibits significantly enhanced rigidity and mechanical strength, achieving 1.4 times the tensile/flexural strength of pure PEI.

Capable of withstanding higher static/dynamic stress, ideal for high-strength and high-rigidity applications.

Heat deflection temperature of JTYPEI®GF30 reaches 210°C, outperforming pure PEI (201°C), ensuring better shape and dimensional stability under high temperatures.

Thermal expansion coefficient is half that of JTYPEI®NA, with superior wear resistance, making it suitable for high-friction and thermal cycling environments.

Slightly more challenging to process than pure PEI, but high efficiency and precision can still be achieved through optimized methods and parameters.

Enhanced properties result in superior performance of finished products.

With 30% glass fiber reinforcement, JTYPEI®GF30 exhibits significantly enhanced rigidity and mechanical strength, achieving 1.4 times the tensile/flexural strength of pure PEI.

Capable of withstanding higher static/dynamic stress, ideal for high-strength and high-rigidity applications.

Heat deflection temperature of JTYPEI®GF30 reaches 210°C, outperforming pure PEI (201°C), ensuring better shape and dimensional stability under high temperatures.

Thermal expansion coefficient is half that of JTYPEI®NA, with superior wear resistance, making it suitable for high-friction and thermal cycling environments.

Slightly more challenging to process than pure PEI, but high efficiency and precision can still be achieved through optimized methods and parameters.

Enhanced properties result in superior performance of finished products.

JTYPEI®GF30 is designed for high-stress, impact, or fatigue-prone environments, including:

Automotive: Components, interior/exterior trim

Industrial: Precision bearings, mechanical load-bearing parts, wind power equipment

Electronics/Energy: Semiconductor processing, new energy battery components, electrical systems

JTYPEI®GF30 is designed for high-stress, impact, or fatigue-prone environments, including:

Automotive: Components, interior/exterior trim

Industrial: Precision bearings, mechanical load-bearing parts, wind power equipment

Electronics/Energy: Semiconductor processing, new energy battery components, electrical systems