- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

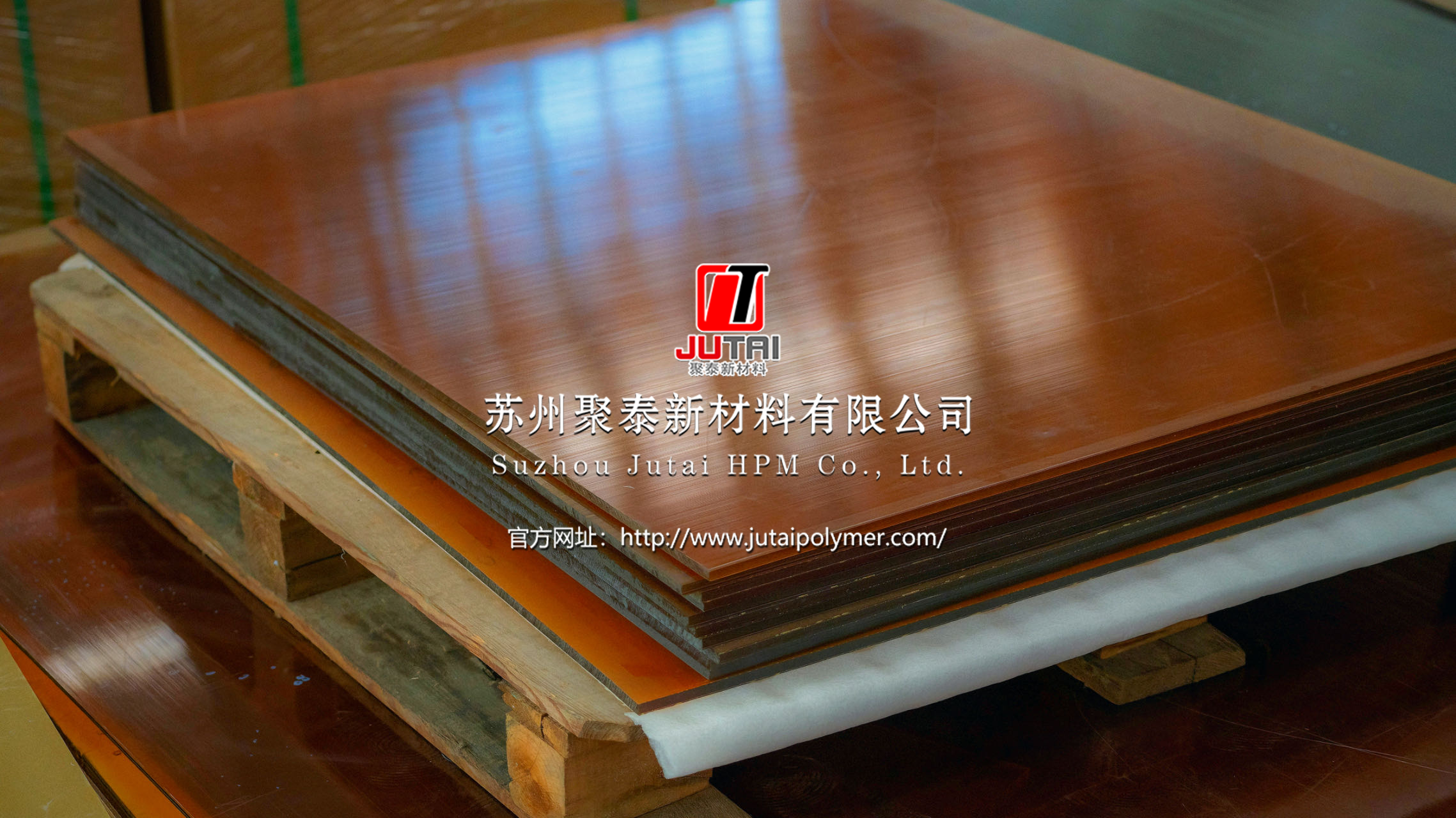

Polyetherimide ,Abbreviation: PEI

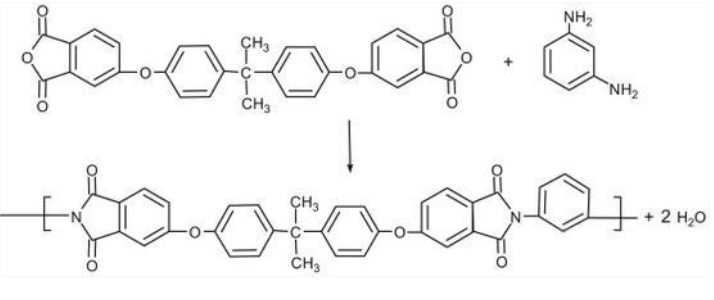

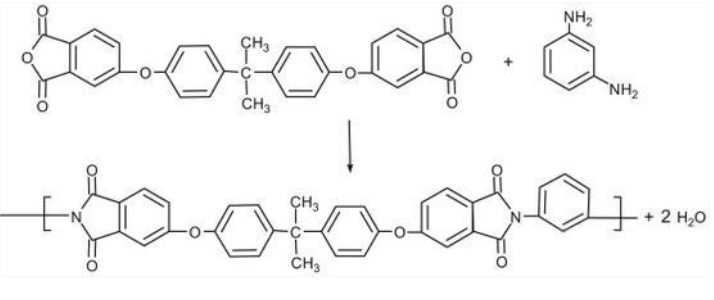

Molecular Structure:

PEI is a semi-crystalline high-performance polymer composed of aromatic rings, ether bonds (-O-), and imide rings (-CO-N-). These structural elements provide exceptional thermal stability, dimensional accuracy, and mechanical strength.

Outstanding heat resistance and dimensional accuracy

Higher strength and rigidity than PPS and PSU

Excellent electrical insulation and low smoke flame retardancy

Ideal replacement for metal components in high-tech industries

For PEI sheets, rods, machined parts, or custom components, feel free to contact us for technical support, material selection, and machining services.

Polyetherimide ,Abbreviation: PEI

Molecular Structure:

PEI is a semi-crystalline high-performance polymer composed of aromatic rings, ether bonds (-O-), and imide rings (-CO-N-). These structural elements provide exceptional thermal stability, dimensional accuracy, and mechanical strength.

Outstanding heat resistance and dimensional accuracy

Higher strength and rigidity than PPS and PSU

Excellent electrical insulation and low smoke flame retardancy

Ideal replacement for metal components in high-tech industries

For PEI sheets, rods, machined parts, or custom components, feel free to contact us for technical support, material selection, and machining services.

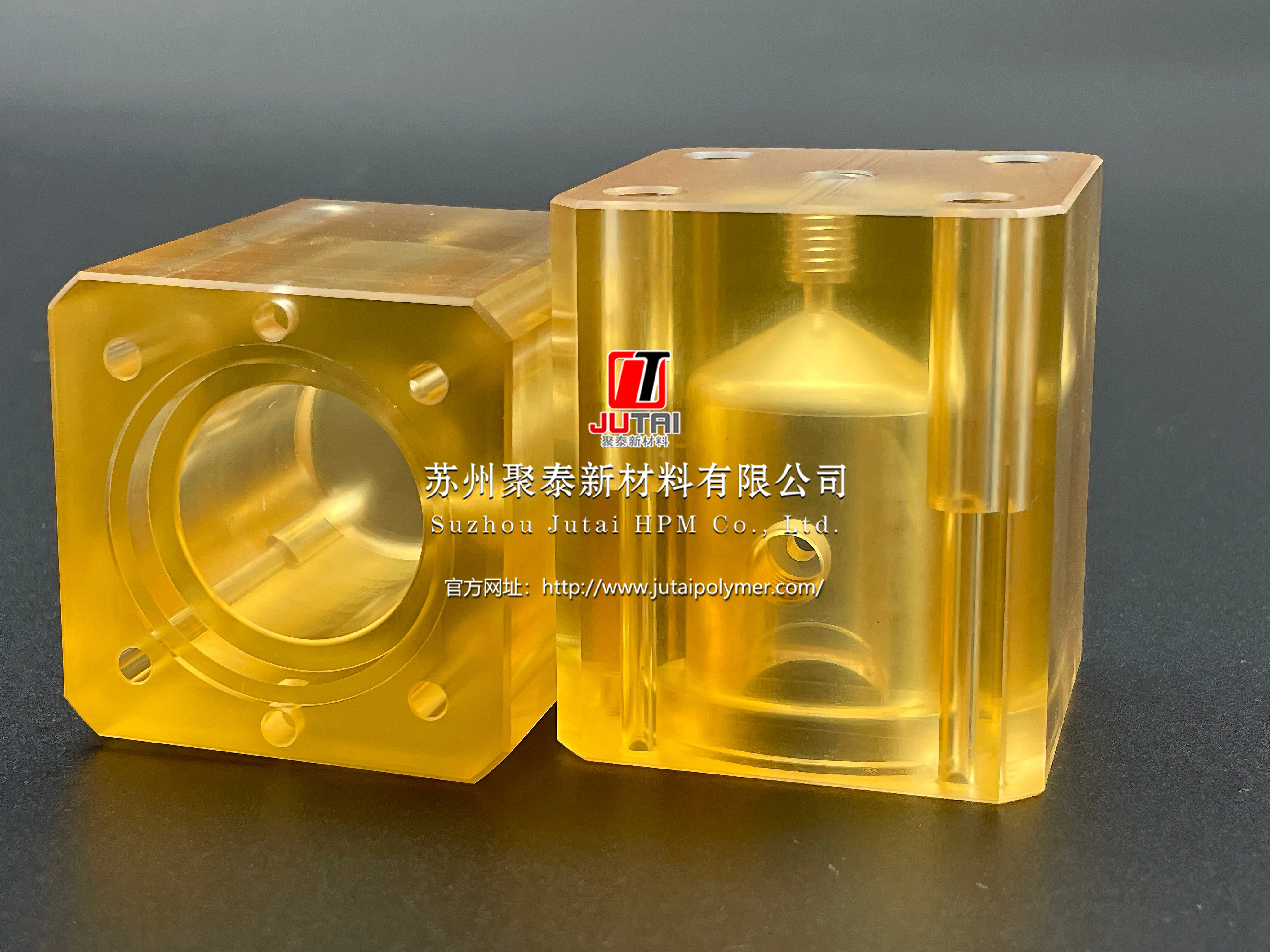

Appearance: Transparent amber color, non-toxic, odorless.

Dimensional Stability: Excellent dimensional precision with low and stable molding shrinkage.

Unreinforced PEI: 0.5% – 0.7%

Glass fiber reinforced: 0.1% – 0.3%

Water absorption: 0.16%

Low Thermal Expansion: Similar to metals, ideal for high-precision components.

High Strength and Modulus:

Tensile strength: up to 15,000 psi

Retains 6,000 psi even at 190°C

Flexural modulus (20% GF): up to 1,700,000 psi

Toughness: Elongation at break 60% – 80%, suitable for snap-fit and structural designs.

Excellent Creep & Fatigue Resistance

Impact Strength: Sensitive to notches, but proper design ensures high impact performance.

Long-term service temperature: 150°C – 170°C

Heat deflection temperature (HDT): up to 220°C

Glass transition temperature (Tg): 217°C

Short-term resistance: Withstands 180°C – 200°C without degradation

Thermal stability: Maintains strength, rigidity, and wear resistance under high heat.

Natural flame resistance—no additives required

Oxygen Index: 47%

Flammability Rating: UL94 V-0

Emits low smoke and toxicity.

Excellent resistance to hydrocarbons, alcohols, oils, halogenated solvents, inorganic acids, and short-term weak alkalis.

Resistant to hot water and hydrolysis: retains 85% tensile strength after 104 hours in boiling water.

Limited alkali resistance and dissolves in some solvents at temperatures ≥150°C.

Stable dielectric constant, low dielectric loss, and high dielectric strength across a wide temperature and frequency range.

Ideal for high-performance electronic and electrical insulation components.

| Property | Value | Property | Value |

|---|---|---|---|

| Specific Heat Capacity | 1.1 J/(g·℃) | Flow Temperature | >330°C |

| Thermal Conductivity | 0.9 kJ/(m·h·℃) | HDT | 200°C |

| Coefficient of Thermal Expansion | 5.62 x 10⁻⁵ /℃ | Dielectric Constant (10⁶ Hz) | 3.2 – 3.4 |

| Molding Shrinkage | 0.5% | Dielectric Loss (10⁶ Hz) | (3–8)×10⁻⊃3; |

| Oxygen Index | 40% | Volume Resistivity | 10⊃1;⁶ Ω·cm |

| Property | Value | Property | Value |

|---|---|---|---|

| Specific Heat Capacity | 1.1 J/(g·℃) | Flow Temperature | >330°C |

| Thermal Conductivity | 0.9 kJ/(m·h·℃) | HDT | 200°C |

| Coefficient of Thermal Expansion | 5.62 x 10⁻⁵ /℃ | Dielectric Constant (10⁶ Hz) | 3.2 – 3.4 |

| Molding Shrinkage | 0.5% | Dielectric Loss (10⁶ Hz) | (3–8)×10⁻⊃3; |

| Oxygen Index | 40% | Volume Resistivity | 10⊃1;⁶ Ω·cm |

Excellent UV and gamma radiation resistance.

Tensile strength remains at 94% after exposure to 400-megarad cobalt irradiation.

Suitable for injection molding, extrusion, blow molding, and 3D printing.

Must be pre-dried before processing due to moisture absorption.

Appearance: Transparent amber color, non-toxic, odorless.

Dimensional Stability: Excellent dimensional precision with low and stable molding shrinkage.

Unreinforced PEI: 0.5% – 0.7%

Glass fiber reinforced: 0.1% – 0.3%

Water absorption: 0.16%

Low Thermal Expansion: Similar to metals, ideal for high-precision components.

High Strength and Modulus:

Tensile strength: up to 15,000 psi

Retains 6,000 psi even at 190°C

Flexural modulus (20% GF): up to 1,700,000 psi

Toughness: Elongation at break 60% – 80%, suitable for snap-fit and structural designs.

Excellent Creep & Fatigue Resistance

Impact Strength: Sensitive to notches, but proper design ensures high impact performance.

Long-term service temperature: 150°C – 170°C

Heat deflection temperature (HDT): up to 220°C

Glass transition temperature (Tg): 217°C

Short-term resistance: Withstands 180°C – 200°C without degradation

Thermal stability: Maintains strength, rigidity, and wear resistance under high heat.

Natural flame resistance—no additives required

Oxygen Index: 47%

Flammability Rating: UL94 V-0

Emits low smoke and toxicity.

Excellent resistance to hydrocarbons, alcohols, oils, halogenated solvents, inorganic acids, and short-term weak alkalis.

Resistant to hot water and hydrolysis: retains 85% tensile strength after 104 hours in boiling water.

Limited alkali resistance and dissolves in some solvents at temperatures ≥150°C.

Stable dielectric constant, low dielectric loss, and high dielectric strength across a wide temperature and frequency range.

Ideal for high-performance electronic and electrical insulation components.

| Property | Value | Property | Value |

|---|---|---|---|

| Specific Heat Capacity | 1.1 J/(g·℃) | Flow Temperature | >330°C |

| Thermal Conductivity | 0.9 kJ/(m·h·℃) | HDT | 200°C |

| Coefficient of Thermal Expansion | 5.62 x 10⁻⁵ /℃ | Dielectric Constant (10⁶ Hz) | 3.2 – 3.4 |

| Molding Shrinkage | 0.5% | Dielectric Loss (10⁶ Hz) | (3–8)×10⁻⊃3; |

| Oxygen Index | 40% | Volume Resistivity | 10⊃1;⁶ Ω·cm |

| Property | Value | Property | Value |

|---|---|---|---|

| Specific Heat Capacity | 1.1 J/(g·℃) | Flow Temperature | >330°C |

| Thermal Conductivity | 0.9 kJ/(m·h·℃) | HDT | 200°C |

| Coefficient of Thermal Expansion | 5.62 x 10⁻⁵ /℃ | Dielectric Constant (10⁶ Hz) | 3.2 – 3.4 |

| Molding Shrinkage | 0.5% | Dielectric Loss (10⁶ Hz) | (3–8)×10⁻⊃3; |

| Oxygen Index | 40% | Volume Resistivity | 10⊃1;⁶ Ω·cm |

Excellent UV and gamma radiation resistance.

Tensile strength remains at 94% after exposure to 400-megarad cobalt irradiation.

Suitable for injection molding, extrusion, blow molding, and 3D printing.

Must be pre-dried before processing due to moisture absorption.

Used for high-temperature and structural components such as:

Engine parts, ignition components, temperature control housings

Gears, bearings, solenoid valve bodies

Headlight reflectors, lamp holders, electrical connectors

Vacuum pump impellers, oil-resistant components

PEI is widely used in:

Fiber optic connectors

Optical modules

Precision optical components

Ideal for:

Aircraft interior panels and components

Engine parts and jet propulsion systems

Lightweight EMI-shielding structures

Used for:

Connectors, relays, switches, PCB components

Precision molded optical fiber devices

High-performance electric motor components

Replaces metals in optical fiber connectors for better performance and reduced cost.

Suitable for:

Surgical instruments

Medical monitoring device housings

Sterilizable reusable and disposable medical components

Used for high-temperature and structural components such as:

Engine parts, ignition components, temperature control housings

Gears, bearings, solenoid valve bodies

Headlight reflectors, lamp holders, electrical connectors

Vacuum pump impellers, oil-resistant components

PEI is widely used in:

Fiber optic connectors

Optical modules

Precision optical components

Ideal for:

Aircraft interior panels and components

Engine parts and jet propulsion systems

Lightweight EMI-shielding structures

Used for:

Connectors, relays, switches, PCB components

Precision molded optical fiber devices

High-performance electric motor components

Replaces metals in optical fiber connectors for better performance and reduced cost.

Suitable for:

Surgical instruments

Medical monitoring device housings

Sterilizable reusable and disposable medical components

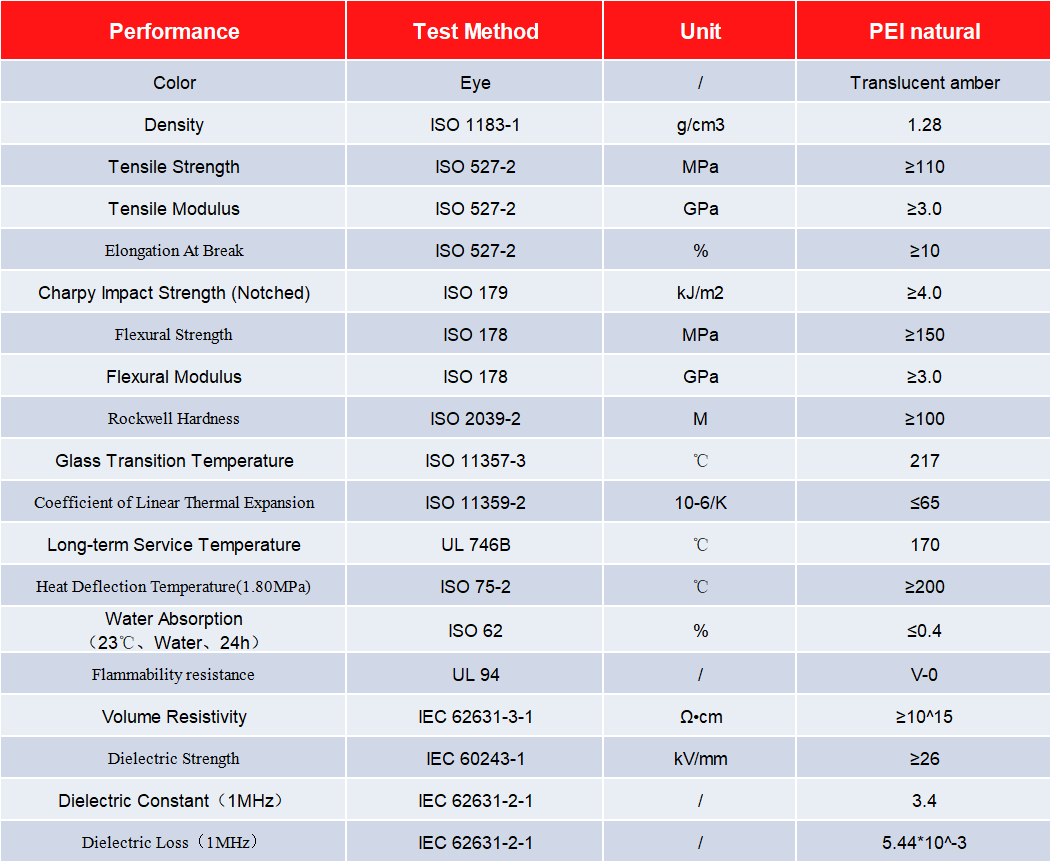

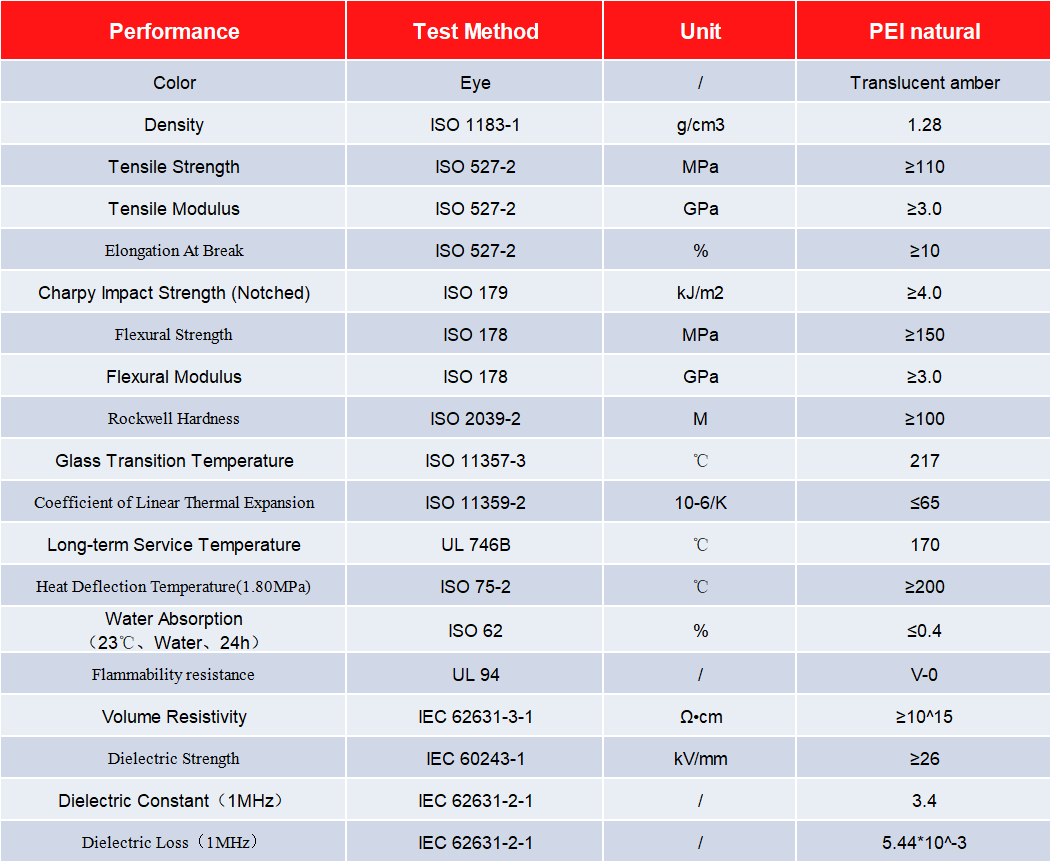

Technical Data Sheet

Technical Data Sheet

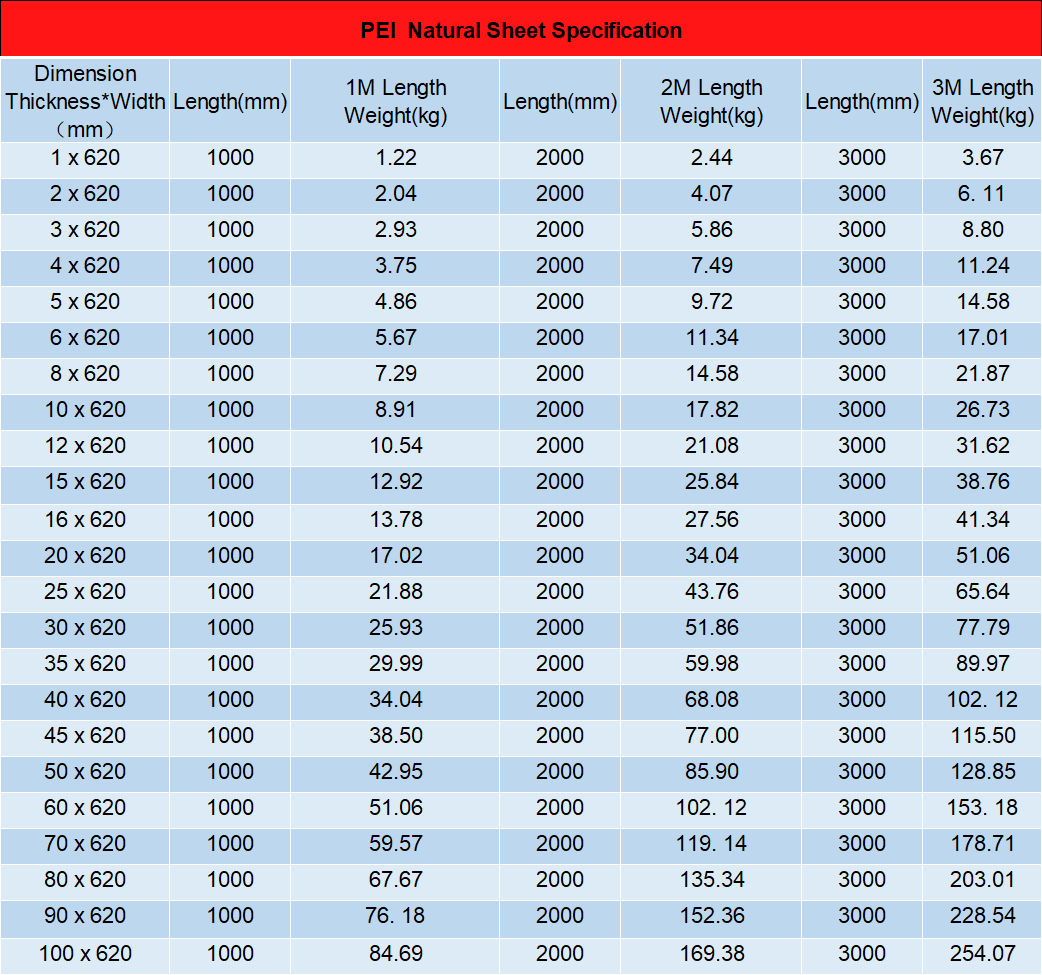

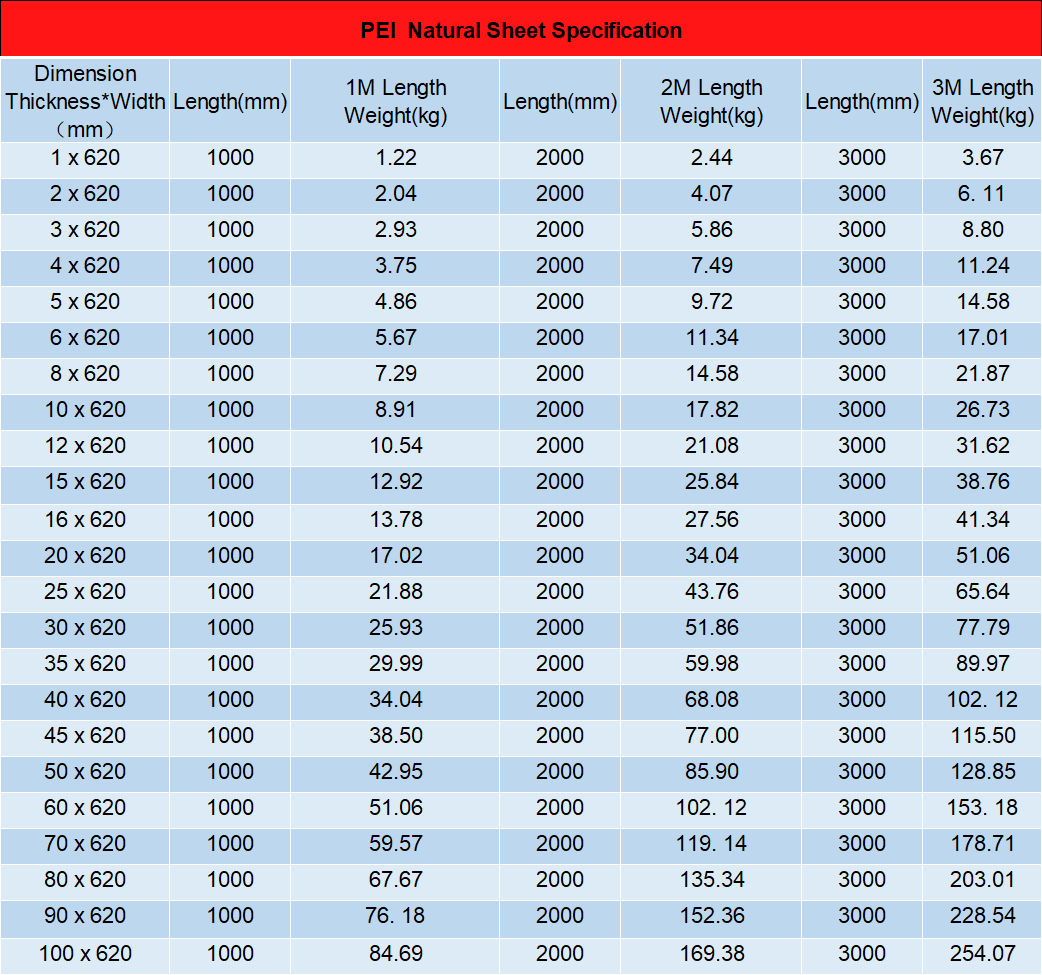

PEI Sheet Specification

PEI Sheet Specification