- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

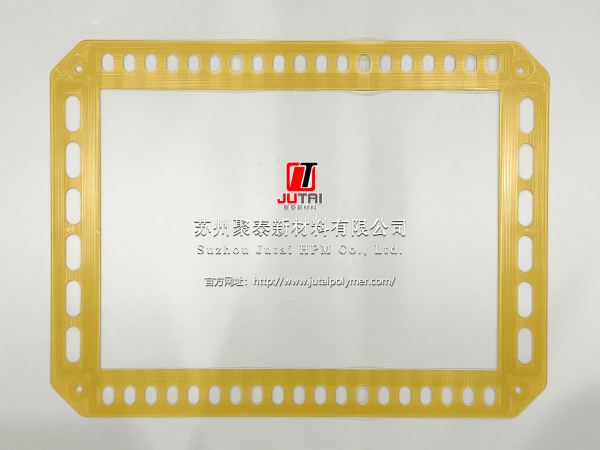

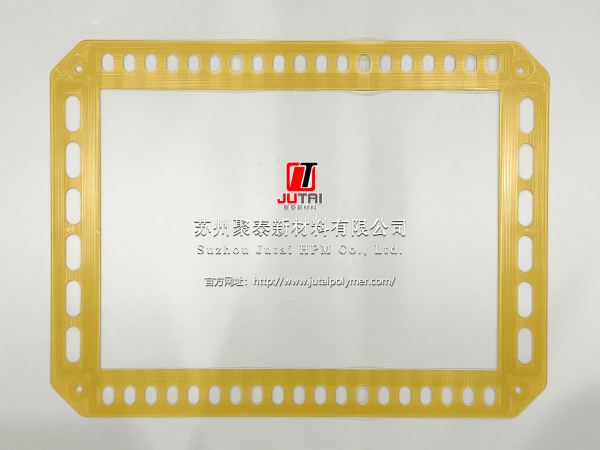

| Suzhou Jutai New Materials Co., Ltd. is a leading manufacturer and precision machining specialist in high-performance thermoplastics. We specialize in PEI (Polyetherimide, Ultem®) materials, offering a comprehensive solution from raw material supply to the delivery of high-tolerance machined components. | |||||||||

JTYPEI®NA (Ultem) material is an outstanding high-performance thermoplastic, ideal for the most demanding environments. Key advantages include:

Exceptional Thermal Stability: Continuous use temperature up to 170°C (338°F).

Inherent Flame Resistance: Complies with UL 94 V-0 without harmful additives, featuring low smoke and toxicity.

High Strength & Stiffness: Excellent mechanical properties are retained at elevated temperatures.

Excellent Electrical Insulation: Stable dielectric strength across a wide frequency and temperature range.

Chemical Resistance: Withstands a broad range of chemicals, including alcohols, hydrocarbons, and most acids.

High Purity & Low Outgassing: Ideal for cleanroom and high-vacuum applications.

JTYPEI®NA (Ultem) material is an outstanding high-performance thermoplastic, ideal for the most demanding environments. Key advantages include:

Exceptional Thermal Stability: Continuous use temperature up to 170°C (338°F).

Inherent Flame Resistance: Complies with UL 94 V-0 without harmful additives, featuring low smoke and toxicity.

High Strength & Stiffness: Excellent mechanical properties are retained at elevated temperatures.

Excellent Electrical Insulation: Stable dielectric strength across a wide frequency and temperature range.

Chemical Resistance: Withstands a broad range of chemicals, including alcohols, hydrocarbons, and most acids.

High Purity & Low Outgassing: Ideal for cleanroom and high-vacuum applications.

Key Applications Across Industries

We manufacture precision PEI parts for a wide range of high-tech sectors:

Aerospace: Lightweight brackets, cabin interior components, ducting parts, and insulation components that must meet stringent FST (Flame, Smoke, Toxicity) standards.

Semiconductor & Electronics: Wafer handling fixtures, test sockets, vacuum wand arms, plasma resistant components, and insulating jigs.

Medical & Healthcare: Surgical instrument handles, tooling trays, and housings that can withstand repeated sterilization (autoclave, EtO, radiation).

Industrial Automation: High-temperature jigs, fixtures, insulators, and bearings for automated assembly and testing equipment.

Key Applications Across Industries

We manufacture precision PEI parts for a wide range of high-tech sectors:

Aerospace: Lightweight brackets, cabin interior components, ducting parts, and insulation components that must meet stringent FST (Flame, Smoke, Toxicity) standards.

Semiconductor & Electronics: Wafer handling fixtures, test sockets, vacuum wand arms, plasma resistant components, and insulating jigs.

Medical & Healthcare: Surgical instrument handles, tooling trays, and housings that can withstand repeated sterilization (autoclave, EtO, radiation).

Industrial Automation: High-temperature jigs, fixtures, insulators, and bearings for automated assembly and testing equipment.

Suzhou JUTAI provide full-service support, from supplying standard stock to manufacturing custom parts.

A. Raw Material Stock:

PEI Sheet/Plate: Available in thicknesses from T1mm to 100mm, with a size of 1240mm x 3000mm.

PEI Round Rod/Bar: Available in diameters from 6mm to 200mm, with a standard length of 3000mm.

B. Precision Machining Services:

High-Precision Machining: We achieve tight tolerances down to ±0.005 mm for the most critical dimensions.

Large-Part Capacity: Our CNC machining centers can handle large components with a machining travel of 3000mm x 2500mm.

Expert Craftsmanship: Our team has extensive experience machining PEI to prevent stress cracking and achieve superior surface finishes.

Suzhou JUTAI provide full-service support, from supplying standard stock to manufacturing custom parts.

A. Raw Material Stock:

PEI Sheet/Plate: Available in thicknesses from T1mm to 100mm, with a size of 1240mm x 3000mm.

PEI Round Rod/Bar: Available in diameters from 6mm to 200mm, with a standard length of 3000mm.

B. Precision Machining Services:

High-Precision Machining: We achieve tight tolerances down to ±0.005 mm for the most critical dimensions.

Large-Part Capacity: Our CNC machining centers can handle large components with a machining travel of 3000mm x 2500mm.

Expert Craftsmanship: Our team has extensive experience machining PEI to prevent stress cracking and achieve superior surface finishes.

PEI CNC Machining Video

PEI CNC Machining Video