- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

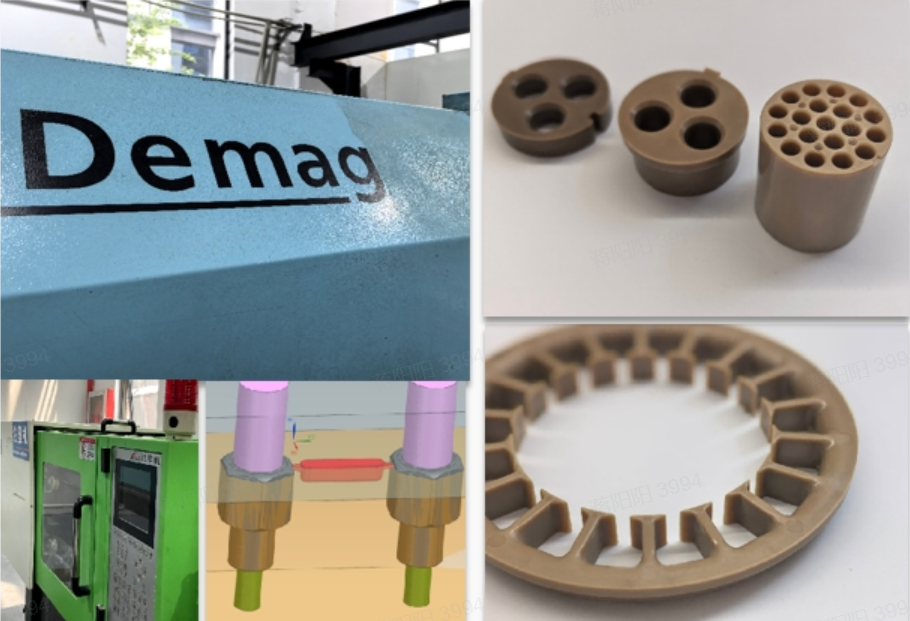

| high-performance plastic injection molding(PEEK, PEI, PSU, PPS), injection molding is particularly suitable for mass-producing complex, high-precision parts with stringent uniformity requirements. | |||||||||

The principle of high-performance plastic injection molding involves heating PEEK/PEI/PSU/PPS to a molten state and injecting it under high pressure into a mold, where it cools and is demolded to form the final product.

This process offers high efficiency and is ideal for mass production, with short cycle times ranging from minutes to even seconds. It enables the manufacturing of complex geometries, thin-walled components, and intricate structures such as threaded snaps. Additionally, it boasts high material utilization with minimal waste, along with excellent product consistency.

As a result, injection molding is particularly suitable for mass-producing complex, high-precision parts with stringent uniformity requirements.

The principle of high-performance plastic injection molding involves heating PEEK/PEI/PSU/PPS to a molten state and injecting it under high pressure into a mold, where it cools and is demolded to form the final product.

This process offers high efficiency and is ideal for mass production, with short cycle times ranging from minutes to even seconds. It enables the manufacturing of complex geometries, thin-walled components, and intricate structures such as threaded snaps. Additionally, it boasts high material utilization with minimal waste, along with excellent product consistency.

As a result, injection molding is particularly suitable for mass-producing complex, high-precision parts with stringent uniformity requirements.

JUTAI's injection molding capabilities ensure the batch production of precision, intricate components.

Injection machine tonnage 50T-500T

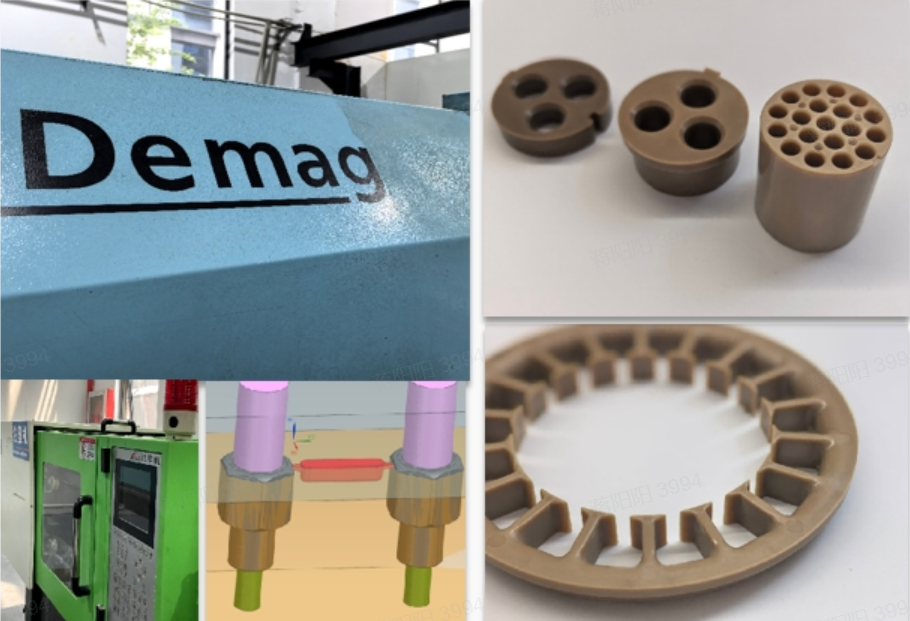

Demag High-precision injection molding equipment

Mold Flow simulation and analysis capability

Cost-efficient comparing to machining

Specialized in high performance plastics including PAEK, PPS, PEI, PFA,PSU etc

JUTAI's injection molding capabilities ensure the batch production of precision, intricate components.

Injection machine tonnage 50T-500T

Demag High-precision injection molding equipment

Mold Flow simulation and analysis capability

Cost-efficient comparing to machining

Specialized in high performance plastics including PAEK, PPS, PEI, PFA,PSU etc