- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

is a modified polyether ether ketone (PEEK) material designed specifically for applications requiring low friction, high wear resistance, and excellent sealing performance.

This grade contains 20% uniformly dispersed PTFE, giving it the lowest coefficient of friction among all ketone-based polymers and superior sliding performance compared with standard unfilled or reinforced PEEK grades.

such as 450FC30 or 450CA30, JUTAIPEEK®WR02 can achieve effective sealing under lower pressures, while maintaining long-term durability and stability.

Its friction coefficient is 50% lower and its wear rate is 25% lower than unfilled PEEK, making it ideal for rotating, sliding, and load-bearing components.

is a modified polyether ether ketone (PEEK) material designed specifically for applications requiring low friction, high wear resistance, and excellent sealing performance.

This grade contains 20% uniformly dispersed PTFE, giving it the lowest coefficient of friction among all ketone-based polymers and superior sliding performance compared with standard unfilled or reinforced PEEK grades.

such as 450FC30 or 450CA30, JUTAIPEEK®WR02 can achieve effective sealing under lower pressures, while maintaining long-term durability and stability.

Its friction coefficient is 50% lower and its wear rate is 25% lower than unfilled PEEK, making it ideal for rotating, sliding, and load-bearing components.

Ultra-low coefficient of friction – lower than any other ketone-based polymer

Enhanced wear resistance – ideal for continuous or intermittent sliding applications

20% PTFE filled for superior lubricity and reduced running temperature

Excellent sealing performance under low pressure

High dimensional stability in demanding environments

Outstanding chemical resistance to fuels, lubricants, solvents, and cleaning agents

Strong mechanical properties with high strength and stiffness

Extended service life compared with unfilled and reinforced PEEK grades

These characteristics make JUTAIPEEK®WR02 one of the best materials for bearing, sealing, and sliding applications.

Ultra-low coefficient of friction – lower than any other ketone-based polymer

Enhanced wear resistance – ideal for continuous or intermittent sliding applications

20% PTFE filled for superior lubricity and reduced running temperature

Excellent sealing performance under low pressure

High dimensional stability in demanding environments

Outstanding chemical resistance to fuels, lubricants, solvents, and cleaning agents

Strong mechanical properties with high strength and stiffness

Extended service life compared with unfilled and reinforced PEEK grades

These characteristics make JUTAIPEEK®WR02 one of the best materials for bearing, sealing, and sliding applications.

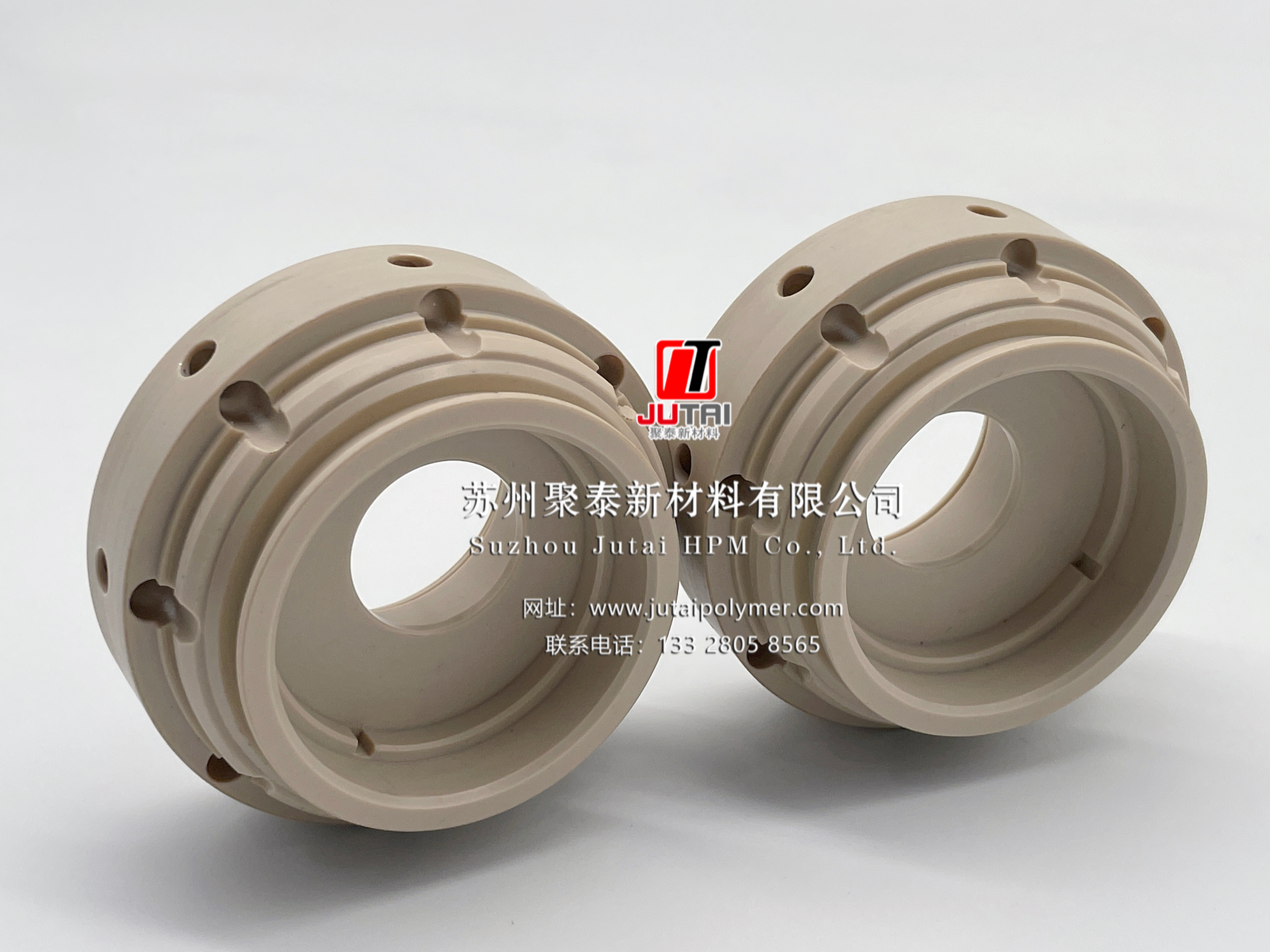

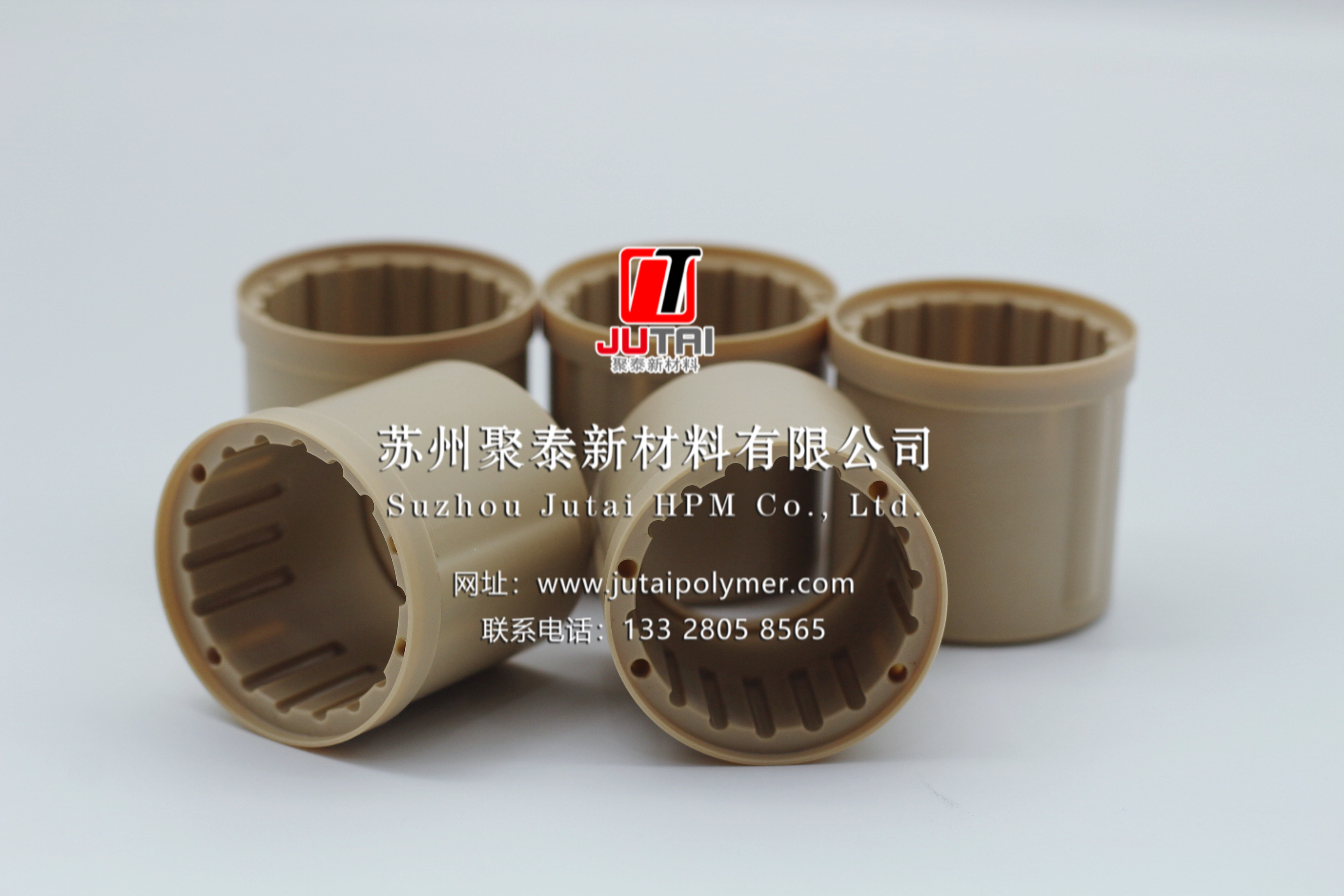

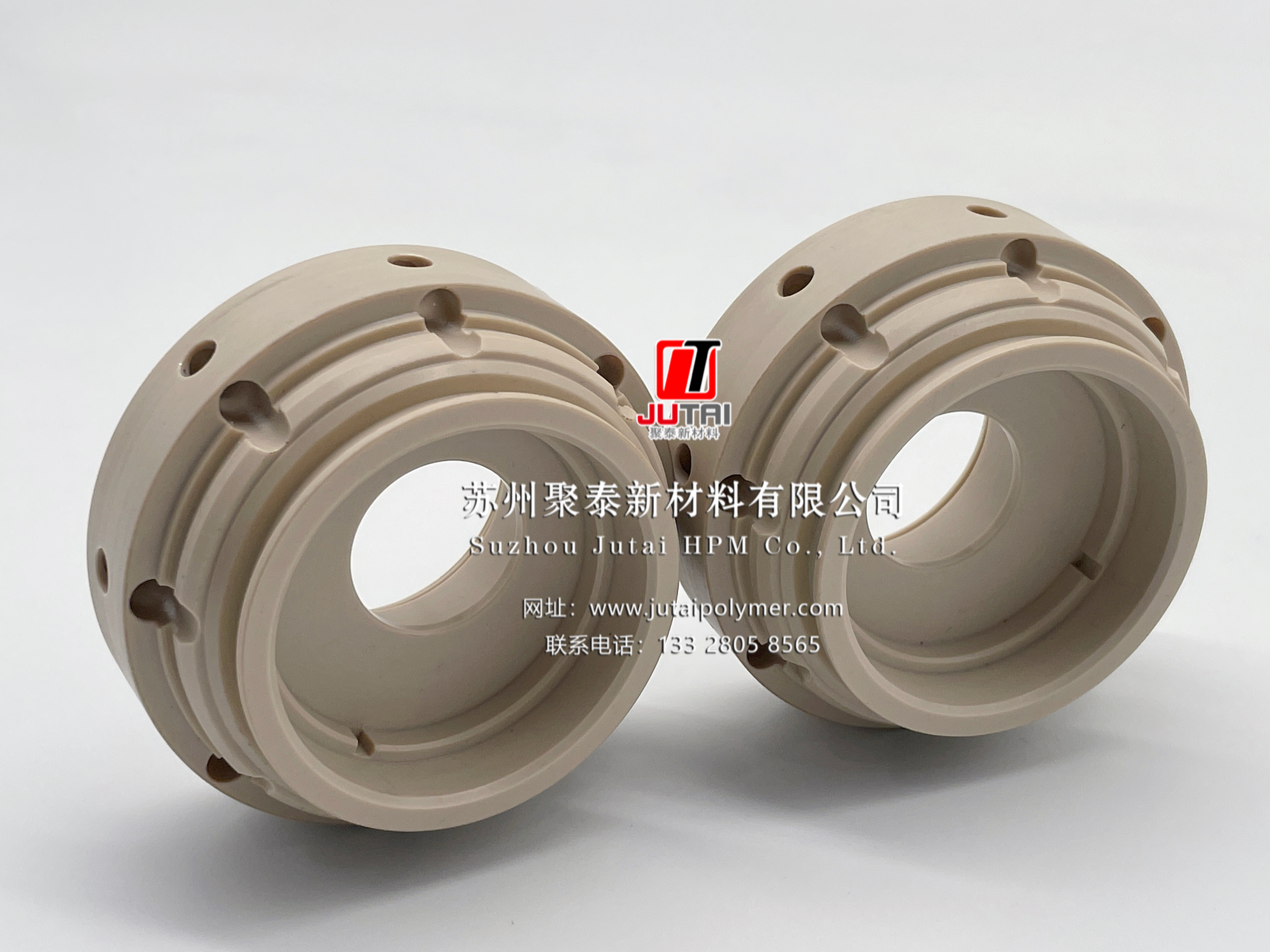

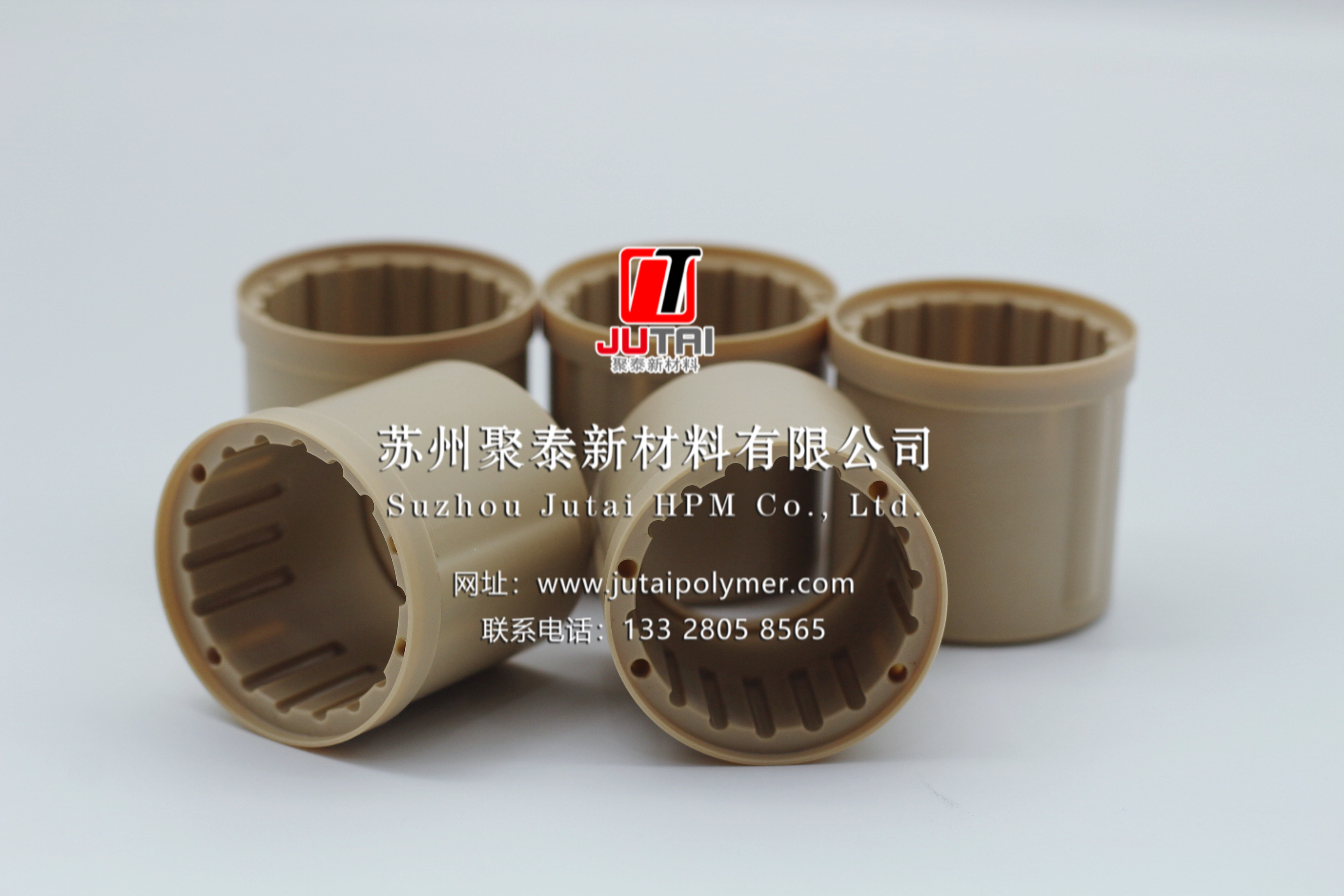

Precision mechanical parts

Insulating and sliding components

Low-friction bushings and guides

Engine bushings

Transmission system components

Brake system wear parts

Sliding and rotating elements that require long service life

Wear-resistant seals

Chemical-resistant sealing components

Low-pressure sealing elements

Wear pads and thrust washers

Sliding plates and guide components

High-strength bushings, rotors, and gears

The combination of wear resistance, low friction, and chemical stability allows Bearing Grade PEEK to perform reliably in harsh and high-load environments.

Precision mechanical parts

Insulating and sliding components

Low-friction bushings and guides

Engine bushings

Transmission system components

Brake system wear parts

Sliding and rotating elements that require long service life

Wear-resistant seals

Chemical-resistant sealing components

Low-pressure sealing elements

Wear pads and thrust washers

Sliding plates and guide components

High-strength bushings, rotors, and gears

The combination of wear resistance, low friction, and chemical stability allows Bearing Grade PEEK to perform reliably in harsh and high-load environments.

| Performance | Test Method | Unit | Bearing Grade PEEK |

| Color | Eye | / | Rice-Yellow |

| Density | ISO 1183-1 | g/cm3 | 1.4 |

| Tensile Strength | ISO 527-2 | MPa | ≥65 |

| Tensile Modulus | ISO 527-2 | GPa | ≥2.5 |

| Elongation At Break | ISO 527-2 | % | ≥10 |

| Charpy Impact Strength | ISO179 | kJ/m2 | ≥4.0 |

| Flexural Strength | ISO 178 | MPa | ≥100 |

| Flexural Modulus | ISO 178 | GPa | ≥2.8 |

| Shore D Hardness | ISO 868 | / | ≥78 |

| Melt Temperature | ISO11357-3 | ℃ | ≥334 |

| Coefficient of Linear Thermal Expansion | ISO 11359-2 | 10-6/K | ≤65 |

| Long Service Temperature | UL 746B | ℃ | 240 |

| Heat Deflection Temperature | ISO 75-2 | ℃ | ≥143 |

| Flame Retardancy | UL 94 | / | V-0 |

| Volume Resistivity | IEC 62631-3-1 | Q ·cm | 10^14-10^16 |

| Frictional Coefficient | ASTM D3702 | / | 0.42±0.10 |

| Wear Rate | um/h | 7.3±1.5 |

Notes: Frictional coefficient and wear rate were tested according to ASTM D3702, that is using thrust washer testing machine. Rubbing pair is PEEK sample thrust washer and 45# steel washer, and the contact area is 1.29cm2, and the inner diameter of the PEEK sample is 25mm. The applied load is 0.35MPa and the rubbing velocity is 2m/s.

| Performance | Test Method | Unit | Bearing Grade PEEK |

| Color | Eye | / | Rice-Yellow |

| Density | ISO 1183-1 | g/cm3 | 1.4 |

| Tensile Strength | ISO 527-2 | MPa | ≥65 |

| Tensile Modulus | ISO 527-2 | GPa | ≥2.5 |

| Elongation At Break | ISO 527-2 | % | ≥10 |

| Charpy Impact Strength | ISO179 | kJ/m2 | ≥4.0 |

| Flexural Strength | ISO 178 | MPa | ≥100 |

| Flexural Modulus | ISO 178 | GPa | ≥2.8 |

| Shore D Hardness | ISO 868 | / | ≥78 |

| Melt Temperature | ISO11357-3 | ℃ | ≥334 |

| Coefficient of Linear Thermal Expansion | ISO 11359-2 | 10-6/K | ≤65 |

| Long Service Temperature | UL 746B | ℃ | 240 |

| Heat Deflection Temperature | ISO 75-2 | ℃ | ≥143 |

| Flame Retardancy | UL 94 | / | V-0 |

| Volume Resistivity | IEC 62631-3-1 | Q ·cm | 10^14-10^16 |

| Frictional Coefficient | ASTM D3702 | / | 0.42±0.10 |

| Wear Rate | um/h | 7.3±1.5 |

Notes: Frictional coefficient and wear rate were tested according to ASTM D3702, that is using thrust washer testing machine. Rubbing pair is PEEK sample thrust washer and 45# steel washer, and the contact area is 1.29cm2, and the inner diameter of the PEEK sample is 25mm. The applied load is 0.35MPa and the rubbing velocity is 2m/s.

PEEKWR02 Sheet Specification | ||

Dimension | Length(mm) | Weight(kg) |

6 x 620 | 1000 | 6.74 |

8 x 620 | 1000 | 8.99 |

10 x 620 | 1000 | 10.78 |

12 x 620 | 1000 | 12.58 |

15 x 620 | 1000 | 15.72 |

16 x 620 | 1000 | 17.08 |

20 x 620 | 1000 | 20.67 |

25 x 620 | 1000 | 25.17 |

30 x 620 | 1000 | 29.66 |

40 x 620 | 1000 | 38.65 |

50 x 620 | 1000 | 47.52 |

PEEKWR02 Sheet Specification | ||

Dimension | Length(mm) | Weight(kg) |

6 x 620 | 1000 | 6.74 |

8 x 620 | 1000 | 8.99 |

10 x 620 | 1000 | 10.78 |

12 x 620 | 1000 | 12.58 |

15 x 620 | 1000 | 15.72 |

16 x 620 | 1000 | 17.08 |

20 x 620 | 1000 | 20.67 |

25 x 620 | 1000 | 25.17 |

30 x 620 | 1000 | 29.66 |

40 x 620 | 1000 | 38.65 |

50 x 620 | 1000 | 47.52 |