- ENGAGED IN SPECIAL ENGINEERING PLASTIC PRODUCTS -

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

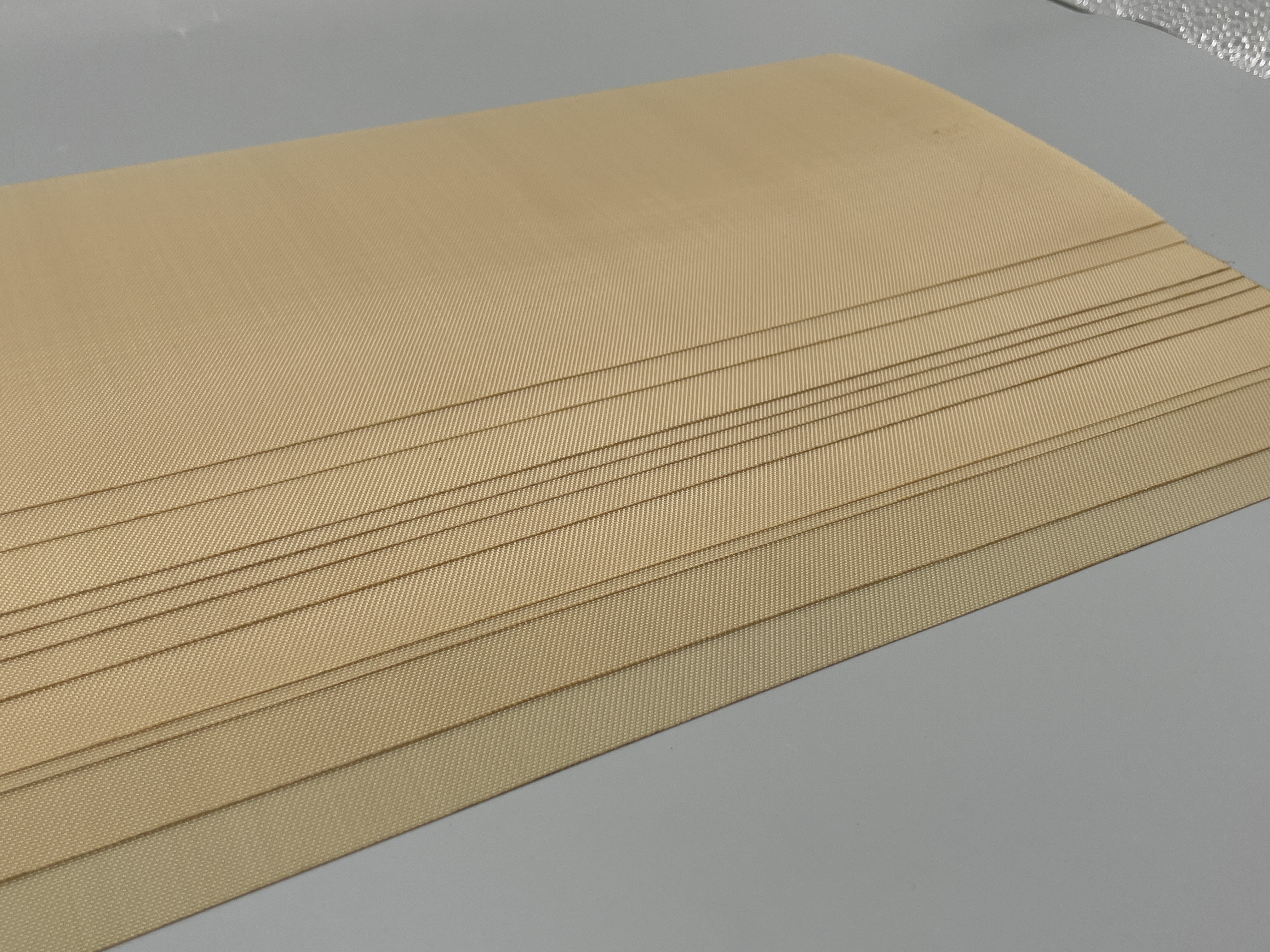

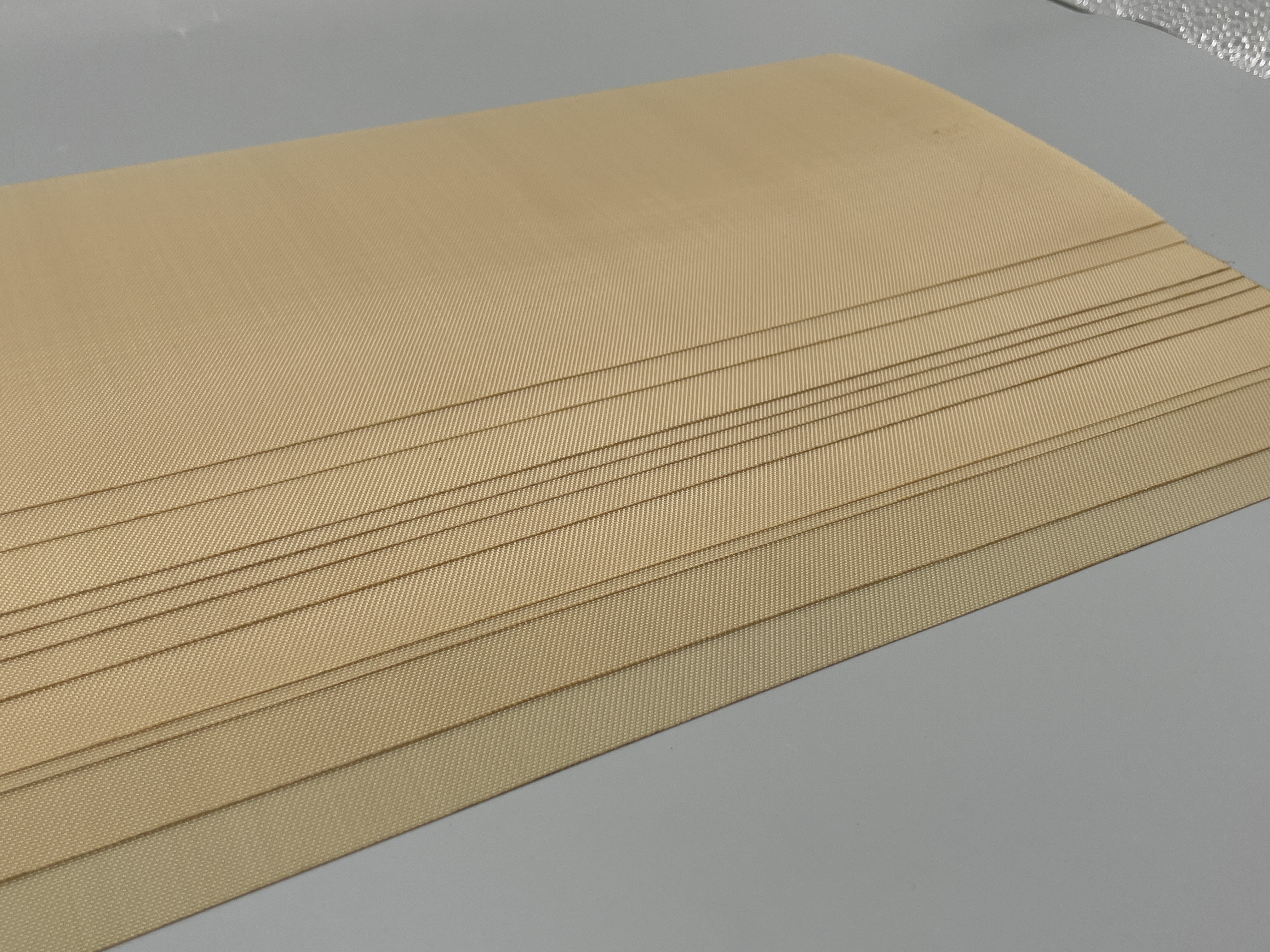

is a thin yet extremely durable high-performance engineering plastic widely used in industries that require materials capable of withstanding high temperature, strong chemicals, and mechanical stress.

offering a unique combination of strength, stability, and chemical resistance, making it suitable for aerospace, automotive, electronics, medical, and industrial applications.

is a thin yet extremely durable high-performance engineering plastic widely used in industries that require materials capable of withstanding high temperature, strong chemicals, and mechanical stress.

offering a unique combination of strength, stability, and chemical resistance, making it suitable for aerospace, automotive, electronics, medical, and industrial applications.

High Temperature Resistance – Continuous operating temperature up to 250°C (482°F)

Excellent Chemical Resistance – Resistant to acids, bases, oils, fuels, and most organic solvents

Superior Mechanical Strength – Maintains high stiffness and load-bearing capability even at elevated temperatures

Outstanding Wear & Abrasion Resistance – Ideal for friction, sliding, and high-load applications

Low Moisture Absorption – Ensures excellent dimensional stability in humid or wet environments

Reliable Electrical Insulation – Suitable for precision electronic and electrical components

High Purity and Excellent Surface Quality – Even at 1mm thickness, the sheet delivers strong rigidity and impact resistance

High Temperature Resistance – Continuous operating temperature up to 250°C (482°F)

Excellent Chemical Resistance – Resistant to acids, bases, oils, fuels, and most organic solvents

Superior Mechanical Strength – Maintains high stiffness and load-bearing capability even at elevated temperatures

Outstanding Wear & Abrasion Resistance – Ideal for friction, sliding, and high-load applications

Low Moisture Absorption – Ensures excellent dimensional stability in humid or wet environments

Reliable Electrical Insulation – Suitable for precision electronic and electrical components

High Purity and Excellent Surface Quality – Even at 1mm thickness, the sheet delivers strong rigidity and impact resistance

High-temperature components

Bearings and bushings

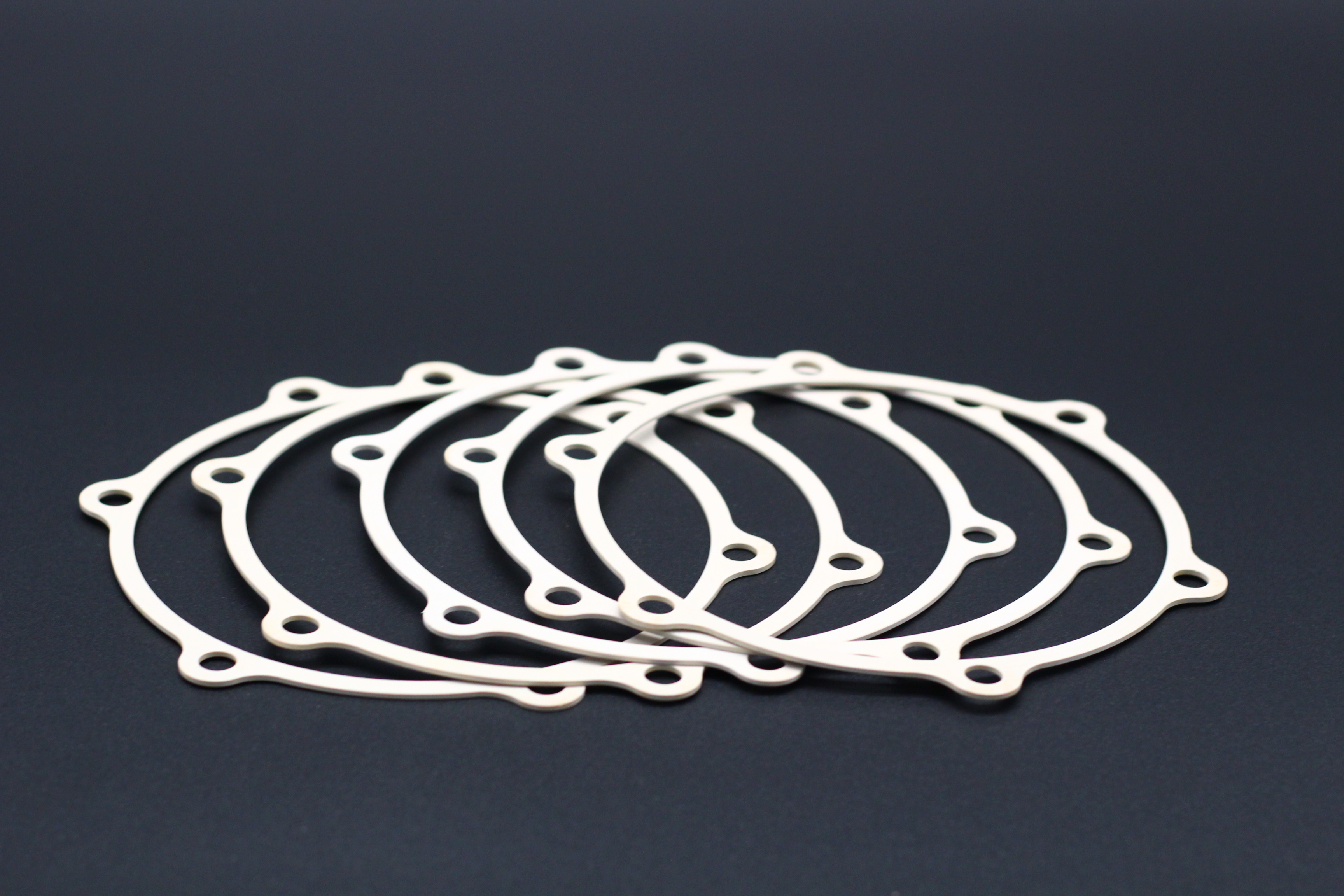

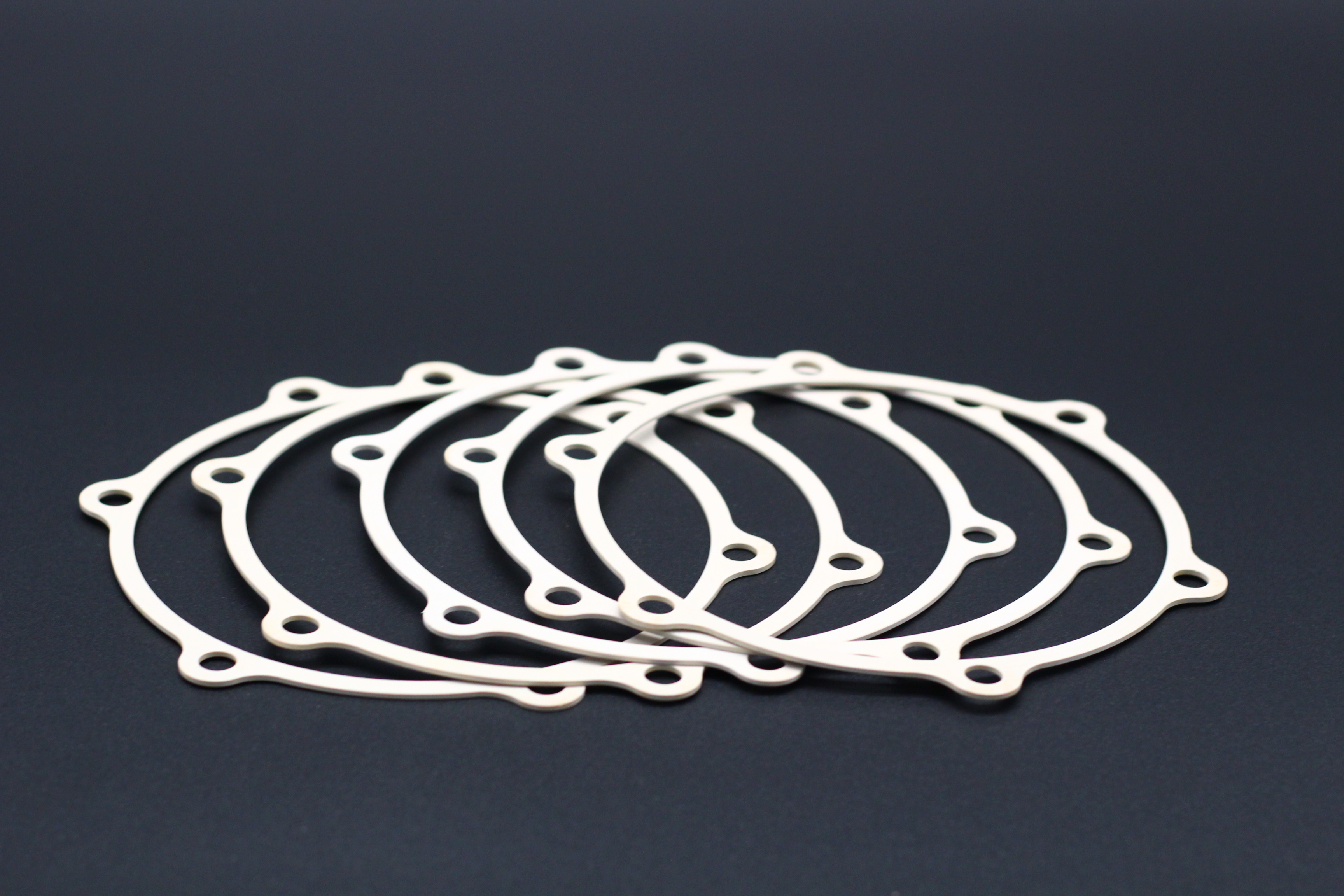

Seals, pump parts, and under-hood components

Lightweight structural components

Insulation materials

High-strength parts exposed to heat and chemicals

Connectors and semiconductor parts

High-frequency insulation components

Precision machined parts

Chemical processing equipment

Wear-resistant mechanical components

High-temperature tooling and fixtures

High-temperature components

Bearings and bushings

Seals, pump parts, and under-hood components

Lightweight structural components

Insulation materials

High-strength parts exposed to heat and chemicals

Connectors and semiconductor parts

High-frequency insulation components

Precision machined parts

Chemical processing equipment

Wear-resistant mechanical components

High-temperature tooling and fixtures

| Performance | Test Method | Unit | PEEK Natural |

| Color | beige | / | Beige |

| Density | ISO 1183-1 | g/cm3 | 1.3 |

| Tensile Strength | ISO 527-2 | MPa | ≥100 |

| Tensile Modulus | ISO 527-2 | GPa | ≥4.0 |

| Elongation At Break | ISO 527-2 | % | ≥25 |

| Charpy Impact Strength (Notched) | ISO 179 | kJ/m2 | ≥4.0 |

| Flexural Strength | ISO 178 | MPa | ≥150 |

| Flexural Modulus | ISO 178 | GPa | ≥3.5 |

| Rockwell Hardness | ISO 2039-2 | M | ≥100 |

| Shore D Hardness | ISO 868 | Shore D | ≥85 |

| Coefficient of Linear Thermal Expansion | ISO 11359-2 | 10-6/K | ≤65 |

| Long-term ServiceTemperature | UL 746B | ℃ | 250 |

| Heat DeflectionTemperature | ISO 75-2 | ℃ | ≥150 |

| Water Absorption (23℃、Water、24h) | ISO 62 | % | ≤0.1 |

| Flammability Resistance (1.6mm) | UL94 | / | V-0 |

| Volume Resistivity | IEC 62631-3-1 | Q-cm | 1014-1016 |

| Dielectric Strength | IEC 60243-1 | kV/mm | ≥15 |

| Dielectric Constant(1MHz) | IEC 62631-2-1 | / | 3.4 |

| Dielectric Loss(1MHz) | IEC 62631-2-1 | / | 0.086 |

| Performance | Test Method | Unit | PEEK Natural |

| Color | beige | / | Beige |

| Density | ISO 1183-1 | g/cm3 | 1.3 |

| Tensile Strength | ISO 527-2 | MPa | ≥100 |

| Tensile Modulus | ISO 527-2 | GPa | ≥4.0 |

| Elongation At Break | ISO 527-2 | % | ≥25 |

| Charpy Impact Strength (Notched) | ISO 179 | kJ/m2 | ≥4.0 |

| Flexural Strength | ISO 178 | MPa | ≥150 |

| Flexural Modulus | ISO 178 | GPa | ≥3.5 |

| Rockwell Hardness | ISO 2039-2 | M | ≥100 |

| Shore D Hardness | ISO 868 | Shore D | ≥85 |

| Coefficient of Linear Thermal Expansion | ISO 11359-2 | 10-6/K | ≤65 |

| Long-term ServiceTemperature | UL 746B | ℃ | 250 |

| Heat DeflectionTemperature | ISO 75-2 | ℃ | ≥150 |

| Water Absorption (23℃、Water、24h) | ISO 62 | % | ≤0.1 |

| Flammability Resistance (1.6mm) | UL94 | / | V-0 |

| Volume Resistivity | IEC 62631-3-1 | Q-cm | 1014-1016 |

| Dielectric Strength | IEC 60243-1 | kV/mm | ≥15 |

| Dielectric Constant(1MHz) | IEC 62631-2-1 | / | 3.4 |

| Dielectric Loss(1MHz) | IEC 62631-2-1 | / | 0.086 |